Safety, Globe and Control Valves with Flat or Angled Seats Maintenance and Reconditioning

Model D - Suitable for valves with flat and angle seats ø 50 - 800mm (2” - 32”)

Valve grinding is an important process for ensuring the proper functioning of industrial valves. The Model D valve grinding machine is a versatile and efficient tool for grinding globe, control, and safety valves with flat or angled seats. With a capacity of ø 50 - 800mm (2” - 32”), this machine is suitable for a wide range of valve sizes. The Model D valve grinding machine is designed for quick and accurate set-up, whether in the workshop or on site. This is achieved through the use of a unique three-segment, adjustable, self-centring jaw chuck that can be mounted directly to the valve body. The self-centring feature ensures that the valve is properly aligned, which leads to a more precise and efficient grinding process.

The Model D valve grinding machine can be supplied with either an electric or pneumatic drive, depending on your specific requirements. The air drive unit is set at 6-7 bar, providing a consistent and reliable grinding performance. Additionally, all drive units have variable grinding speeds, allowing for a more customised approach to valve grinding. The Model D valve grinding machine has individually driven grinding heads, which further increases its versatility. This means that each grinding head can be adjusted independently, allowing for a more precise and uniform grinding process. Moreover, the machine has a fine adjustment of pressure feature, which ensures the precise grinding of the valve surface.

The Model D valve grinding machine comes with self-adhesive grinding discs for quick attachment to the grinding heads. The machine is supplied with rough, medium, and fine grinding discs, ensuring that all necessary grinding stages are covered. Additionally, self-adhesive grinding discs ranging from 40 to 1000 grit are available, as well as diamond grinding discs, providing a wide range of grinding options.

The Model D valve grinding machine has cone segments in different angles available, providing a more customised approach to valve grinding. This feature further enhances the precision and accuracy of the valve grinding process. The Model D valve grinding machine comes with a heavy-duty carrying/storage case for the complete machine and all necessary accessories. This ensures that the machine can be transported and stored safely and easily.

Model D base unit comes in two sizes:

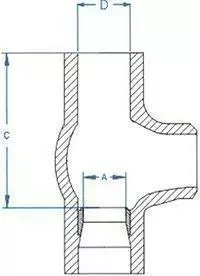

Model DF

Internal diameter A: 40 - 300 mm

External diameter D: 80 - 357 mm

Maximum depth C: 500 mm

Model DG

Internal diameter A: 140 - 861 mm

External diameter D: 150 - 871 mm

Maximum depth C: 1000 mm

Total weight: 50 kg (110 lbs)

Carrying case: 950 x 520 x 370 mm (38” x 21” x 15”)

| Accessories for Model DF |

|---|

| K-AB kit 10-65m m ( 1 /4"-2 1 /2") 15-30-45° Only for electric version |

| K-AB kit 10-65mm (1 /4"-2 1 /2") 15-20-30-37,5-45° Only for electric version |

| K-B kit 8-100mm (1/4"-4") Only for electric version |

| Conical seat segment kit 65-200mm (2 1/2"-8") 15-30-45° |

| Conical seat segment kit 65-200mm (2 1 /2"-8") 15-20-30-37,5-45° |

| Conical seat segment kit 65-300mm (2 1/2"-12") 15-30-45° |

| Conical seat segment kit 65-300mm (2 1/2"-12") 15-20-30-37,5-45° |

| Dust stopper kit 65-200 (2 1 /2"-8") |

| 'Dust stopper kit 250-300mm (10"-12") |

| Drillpress adaptor DF |

| Grinding disc kit FL |

| Driving head o-ring and gear 175mm (7”) |

| Driving head o-ring and gear 225mm (9”) |

| Accessories for Model DG |

|---|

| Drillpress adaptor |

| Grinding disc kit G |