Hardness Testers

Hardness testing has long been one of the most widely used testing procedures conducted on a huge variety of applications ranging from university laboratories for research purposes on new materials to large manufacturers of automotive and aerospace components where standardised material properties are key to the success or failure of a particular component or sub assembly. Coatings and case hardness treatments also need to be able to prove they are as hard as specified, and that the depth of the hardened structural layers match the intended application.

Since the applications for hardness testing are so broad, the variety of machines available also pose what can be a confusing and complex choice of features and software options. Having supplied sample preparation equipment and consumables for over 30 years, Kemet have often found the cost of a hardness tester to be much more than a complete suite of Kemet machines necessary to prepare a sample for hardness testing.

For the majority of applications, the choice of hardness tester does not need to be complicated. The testing is performed according to ISO and ASTM standards which dictate how a unit must calculate sample hardness and how they must be calibrated.

Why Hardness Testing is important?

Hardness testing is an essential tool for analysis, distinguishing different materials, development and improvement of materials and technologies in the context of basic research in the fields of materials science, materials engineering and materials diagnostics. It determines the characteristic values that are of important for assessing the use of materials in industries (suitability of a material for a technically relevant part), for distinguishing between materials (in the case of material confusion) and for clarification of cases of damage (damage analysis).

How does a Hardness Tester work

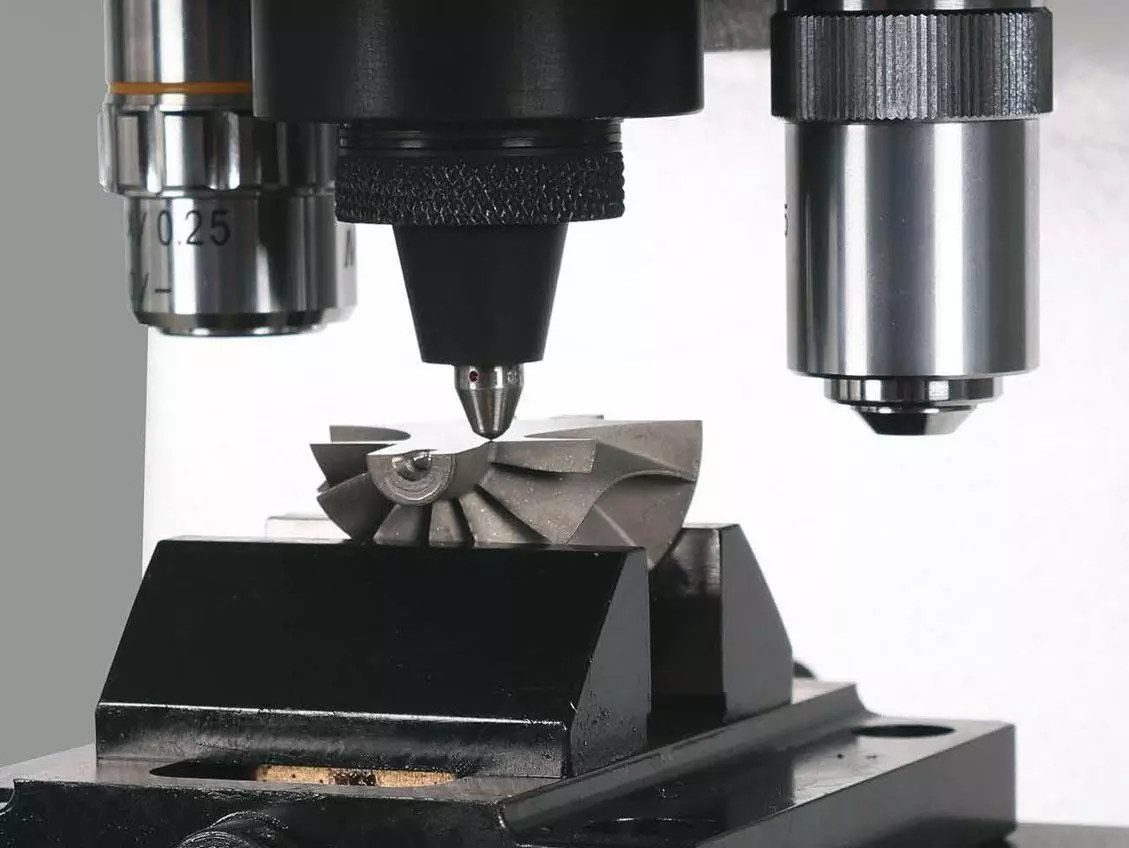

Hardness is a measure of how mechanically resistant a material is to the mechanical penetration of another, harder body (indenter). Diamond is the hardest natural material so is used as an indenter. Methods with static application of the test force are predominantly used for testing the hardness of materials, whereby either the penetration size or depth of the indentation caused by an indenter is measured. A distinction is made with the static hardness testing methods between depth measurement methods and optical measurement methods. Depth measurement methods measure the residual depth of indentation left by the indenter.

Is Hardness Testing non destructive (NDT)

Dependant on the material and application being tested, hardness testing can be non-destructive. If you are doing a hardness test on raw materials like forgings or casting which will require further processing to remove indentation on material, it can be classed as Non-destructive testing (NDT) but if the same hardness testing is done on a critical turbine blade for aerospace NDT, this is considered destructive testing.

Hardness Testing vs Impact Testing

Impact testing measures the material’s capacity to absorb energy when ruptured at high velocity. This gives an indication of the strength of the material and two methods are usually used for impact testing, Charpy or Izod.

Hardness testing assesses the impact of the metal or alloy to permanent indentation, and the depth or size of the indent is measured to determine a hardness value.

Hardness Testers Available

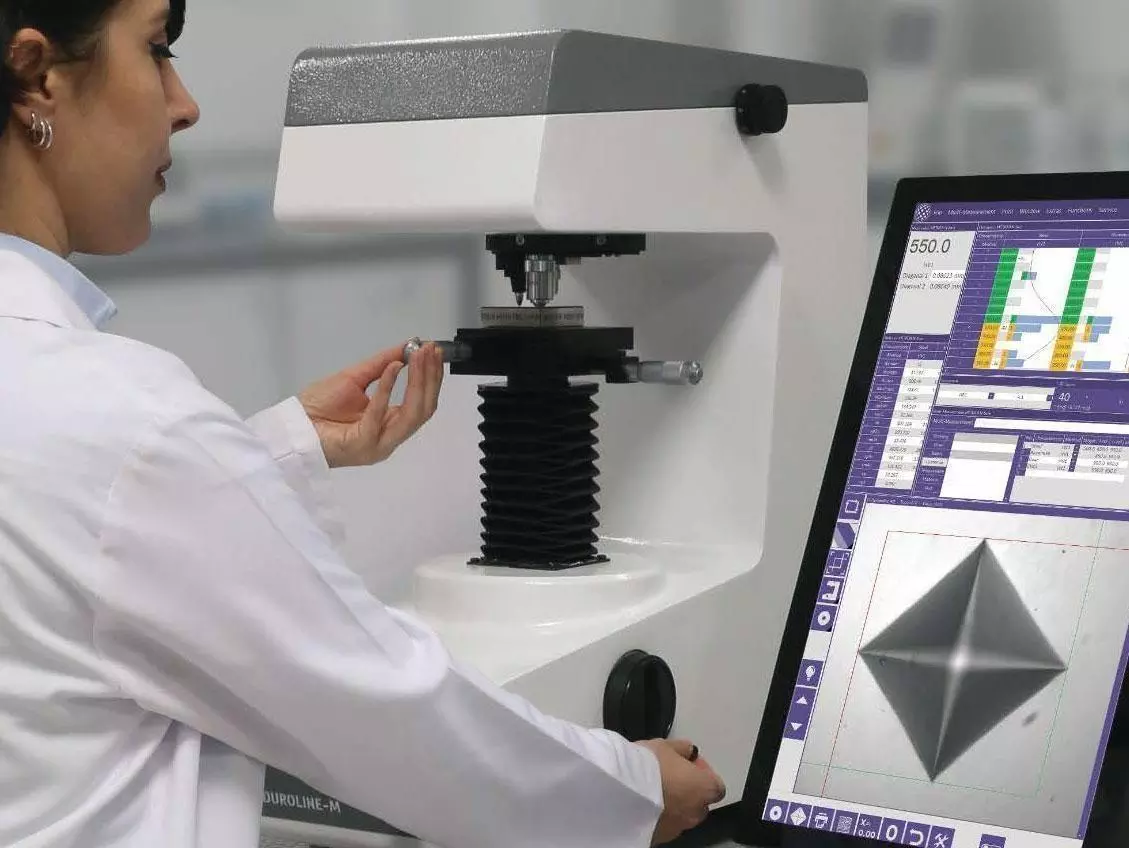

Kemet are delighted to announce the launch of the Metkon Duroline series of hardness testers. A range of benchtop hardness testers for Vickers and Knoop measurement with integrated 22” full HD multi touch monitor. The Metkon N-sure software package is incredibly easy to use and like most machines on the market has the ability for automatic multi measurement when coupled with the automated x/y stage option. The software can automatically generate test reports and has built in CHD, EHT and NHT measurement with automatic contrast and focus for the most accurate results. With a small variety of models, test loads from HV0.01 – HV30 can be accommodated.

Aimed primarily at the material testing laboratory and the smaller component production QA, in particular small precision parts, thin material or wire coatings, the Duroline range has everything you might need at a competitive price.

| M1 | M2 | M4 | V1 | LV1 | LV2 | LV3 | R1 | ||

|---|---|---|---|---|---|---|---|---|---|

| Hardness Scales | Vickers HV as per ISO 6507, ASTM E384, E92 - HV0,01 - HV0,025 - HV0,05 - HV0,1- HV0,2 - HV0,3 - HV0,5 - HV1 | Vickers HV as per ISO 6507, ASTM E384, E92 - HV0,3 - HV0,5 - HV1 - HV2 - HV3 - HV5 - HV10 - HV20 - HV30 | Vickers HV as per ISO 6507, ASTM E384, E92 - HV0,1 - HV0,2 - HV0,3 - HV0,5 - HV1 - HV2 - HV3 - HV5 - HV10 | Rockwell Regular & Superficial Scales as per ISO 6508 & ASTM E18 - HRA, HRBW, HRC, HRD, HREW, HRFW, HRGW, HRHW, HRKW, HRLW, HRMW, HRPW, HRRW, HRSW, HRVW, HR15N, HR30N, HR45N, HR15TW, HR30TW, HR45TW, HR15WW, HR30WW, HR45WW, HR15XW, HR30XW, HR45XW, HR15YW, HR30YW, HR45YW | |||||

| Knoop HK as per ISO 4545, ASTM E384, E92 - HK0,01 - HK0,025 - HK0,05 - HK0,1- HK0,2 - HK0,3 - HK0,5 - HK1 | Knoop HK as per ISO 4545, ASTM E384, E92 - HK0,3 - HK0,5 - HK1 - HK3 | Knoop HK as per ISO 4545, ASTM E384, E92 - HK0,1 - HK0,2 - HK0,3 - HK0,5 - HK1 - HK3 | |||||||

| Test Loads | Test Loads | 10gf – 25gf – 50gf – 100gf – 200gf - 300gf- 500gf - 1000gf | 300gf - 500gf - 1kgf - 2kgf - 3kgf - 5kgf - 10kgf - 20kgf - 30kgf | 100gf, 200gf, 300gf, 500gf, 1kgf, 2kgf, 3kgf, 5kgf, 10kgf | Preload for Superficial Rockwell - 3 kgf. Preload for Rockwell - 10 kgf. Test Loads for Superficial Rockwell - 15 kfg, 30 kgf, 45 kgf. Test Loads for Rockwell - 60kfg, 100kgf, 150kgf. Test Loads for Brinell Depth - 5 kgf to 250 kgf. | ||||

| 0,09807N - 0,2452N - 0,4904N - 0,9807N - 1,961N - 2,942N - 4,904N - 9,807N | 2,942N - 4,904N - 9,807N - 19,631N - 29,420N - 49,033N - 98,067N - 196,033N - 294,200N | 0,9807N - 1,961N - 2,942N - 4,904N - 9,807N - 19,631N - 29,420N - 49,033N - 98,067N | |||||||

| Test Load Accuracy | "10gf - 200gf: +/- 1,5% and > 200gf: +/- 1,0% As per ISO standard (and ASTM E-384, JIS B7725, JIS B7734)" | All loads within +/- 1,0% As per ISO standard (and ASTM E-384, ASTM E-92-17, JIS B7725, JIS B7734) | 10gf - 200gf: +/- 1,5% and > 200gf: +/- 1,0% As per ISO standard (and ASTM E-384, JIS B7725, JIS B7734) | As per ISO 6508 and ASTM E18 | |||||

| Test Load Dwell Time | "from 5 - 99 sec with 1 sec increments As per ISO standard (and ASTM E-384, JIS B7725, JIS B7734)" | ||||||||

| Test Load Application Speed | "10gf - 200gf: < 0.070 mm/s and > 200gf: < 0.200 mm/s As per ISO standard (and ASTM E-384, JIS B7725, JIS B7734)" | For all loads not more than 0.200 mm/s As per ISO standard (and ASTM E-384, JIS B7725, JIS B7734) | 10gf - 200gf: < 0.070 mm/s and > 200gf: < 0.200 mm/s As per ISO standard (and ASTM E-384, JIS B7725, JIS B7734) | ||||||

| Load Force Application | Dead-weight, Automatic motorized, load, dwell, unload | Motorized force application with closed loop load cell control, Automatic load, dwell, unload | |||||||

| Load Selection | Manual by external setting knob | By N-Sure test settings | |||||||

Hardness Testing and its types. Which Hardness Test is best?

Rockwell

The residual depth of the indent made by the indenter is measured. The deeper a defined indenter penetrates at a defined test force into the surface of a specimen, the softer the tested material. The total test force is applied in two stages, this allows the impact of specimen surface roughness (grooves in the specimen) and measuring errors caused by backlash in indentation depth measurement to be eliminated.

Vickers

An optical method, the size of indentation (the diagonals) left by the indenter is measured. In contrast, the depth of indentation caused by the indenter is measured in the depth measurement methods (only Rockwell is standardised). The larger the indent left by the indenter at a defined test force in the surface of a specimen, the softer the tested material. The pyramid-shaped indenter (with interfacial angle of 136°) is pressed into a specimen with a defined test load from 1 gf.

Brinell

An optical method, involving a spherical indenter being pressed into a specimen, the size of indentation left by the indenter is measured. The larger the indent left in the surface of a workpiece (specimen) by the Brinell indenter with a defined ball diameter and a defined test force, the softer the tested material. In order to determine the HBW, the spherical, tungsten carbide indenter is pressed into a specimen with a defined test load (between 1 kgf and 3000 kgf). The results from the quotient of the applied test force (F in newtons (N)) and the surface area of the residual indent on the specimen after withdrawing the test force.

Knoop

An optical method, involving a pyramid-shaped rhombic indenter (longitudinal edge angle 172.5°, transverse edge angle 130°) is pressed into a specimen with a defined test load (between 1 gf and 2 kgf). The larger the indent left by the indenter at a defined test force in the surface of a specimen, the softer the tested material.