Optical Parallels for Assessing Flatness and Parallelism

Optical parallels are highly precise optical instruments designed to assess the flatness and parallelism of micrometre anvils. These specialist components are typically manufactured from premium optical glass or fused silica, materials selected for their outstanding clarity, stability, and resistance to thermal expansion. Given their critical role in precision measurement, optical parallels are produced to exceptionally stringent tolerances, ensuring minimal deviations in both flatness and parallelism. This level of precision is vital for maintaining the accuracy and reliability of micrometres used in high-precision applications.

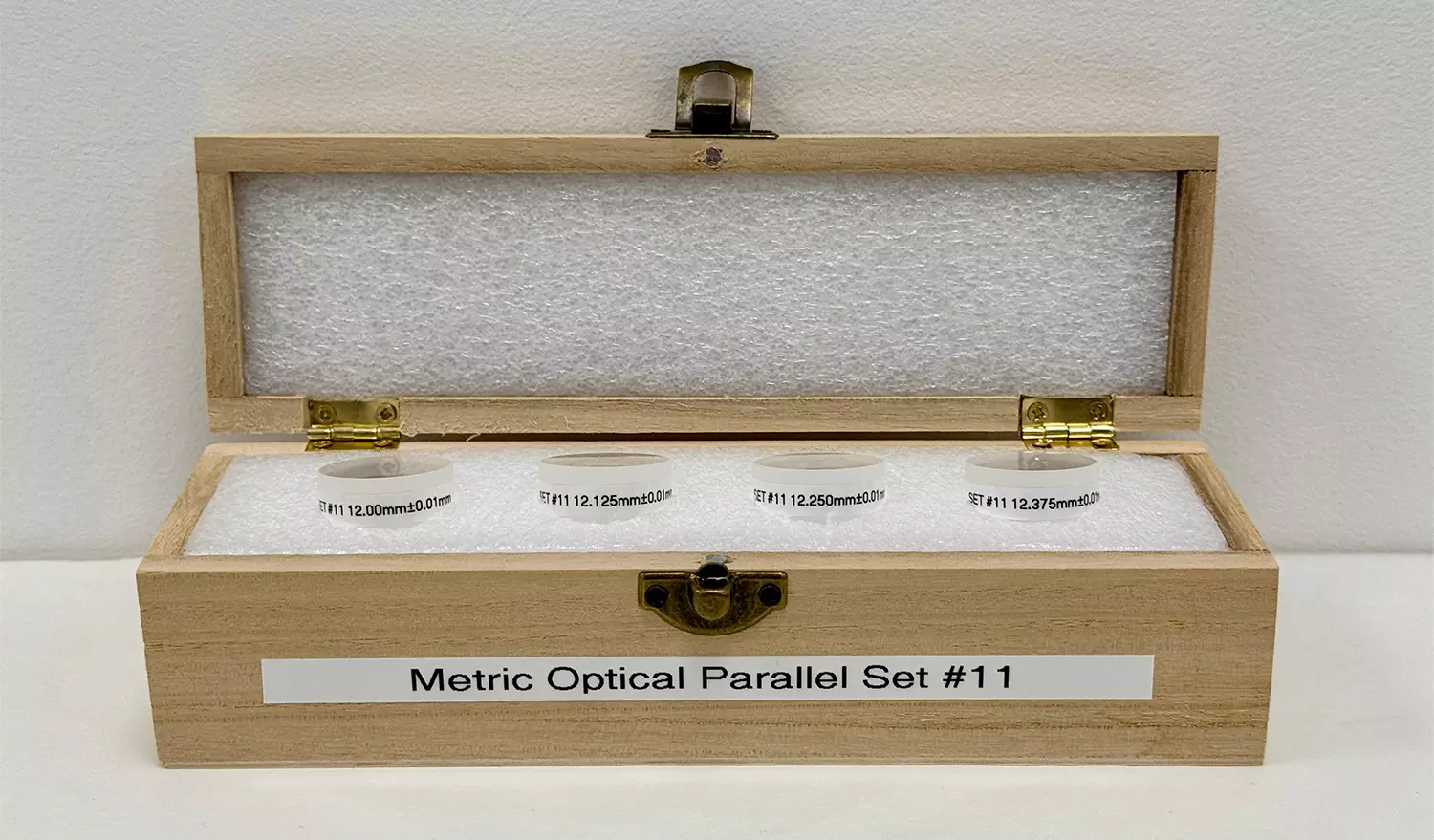

Optical parallels are generally supplied in sets of four, with each parallel specifically designed to evaluate the performance of a micrometre spindle at precise 90-degree rotational increments. By testing at multiple positions, the set offers a thorough assessment of the micrometre’s accuracy, identifying any inconsistencies in flatness or parallelism across various orientations. This systematic approach ensures that the micrometre functions with the highest degree of precision, making optical parallels indispensable tools in quality control and metrology laboratories.

Designed for metric measurements, each parallel has a diameter of 30 mm and adheres to strict precision standards, with a flatness tolerance of 0.1 µm and a parallelism tolerance of 0.2 µm. These optical parallels are specifically intended for use with micrometres in the 0–25 mm range. The set includes four individual parallels: 157-101 (12.0 mm), 157-102 (12.12 mm), 157-103 (12.25 mm), and 157-104 (12.37 mm), ensuring thorough testing and calibration across different measurements.

Why Use Optical Parallels?

Ensuring Measurement Accuracy

Micrometres are widely used in high-precision manufacturing and require regular calibration to maintain their accuracy. Optical parallels provide an effective solution for verifying the flatness and alignment of micrometre anvils, reducing the risk of measurement errors. Even minor imperfections in the anvil surfaces can result in inconsistent readings, making optical parallels an essential tool for ensuring measurement reliability.

High Precision and Stability

Optical parallels are crafted from high-quality optical glass or fused silica, ensuring superior dimensional stability. These materials exhibit minimal thermal expansion, which is crucial for maintaining precision under varying environmental conditions. With flatness and parallelism tolerances typically within 0.1 µm and 0.2 µm respectively, optical parallels rank among the most accurate tools available for micrometre calibration.

Non-Contact Measurement

Unlike mechanical calibration methods that may introduce wear over time, optical parallels offer a non-contact means of verifying micrometre accuracy. This eliminates the risk of damaging or altering the micrometre’s surfaces during inspection, preserving the integrity of both the tool and the calibration reference.

Comprehensive Calibration Approach

Optical parallels are usually supplied in sets, with each parallel designed to test the micrometre spindle at different rotational positions—typically at 90-degree increments. This approach allows for a more thorough evaluation of spindle alignment and anvil flatness, ensuring that errors are detected in multiple orientations rather than just at a single point of contact.

Versatility Across Industries

Optical parallels are extensively used across various industries, including aerospace, automotive, and precision engineering. Any sector that relies on highly accurate micrometre measurements can benefit from the use of optical parallels. They are especially valuable in quality control environments where maintaining compliance with tight tolerances is paramount.