What is Lapping?

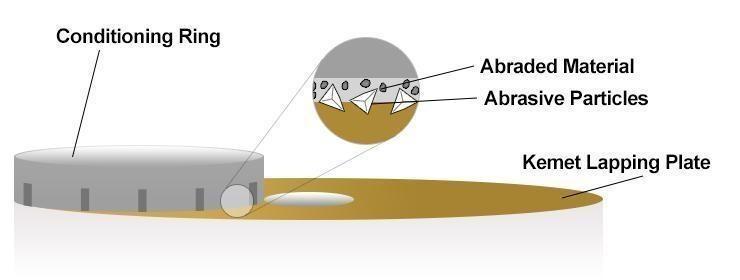

The principle of lapping is simple and based on the cutting power of either a free abrasive grain in a carrier or a fixed abrasive particle within a composite lapping plate matrix.

A lapping plate on which a lapping slurry has been applied moves under the workpiece surface whilst the workpiece rotates on the lapping plate. The uniform abrasive layer between the lapping plate and the workpiece gently remove material from all the contacting areas simultaneously meaning very little stress is put into the workpiece. Ultimately when the whole workpiece has been lapped it will mirror the shape of the lapping plate. For this reason, flat lapping machines are able to generate incredibly flat workpieces.

Although it seems as if the abrasive grains are working in a free movement, this is not entirely true. Depending on the lapping process used abrasive particles are either freely rolling or sliding between the workpiece and lapping plate, or with diamond lapping, the abrasive particles become fixed within the composite lapping plate matrix. Due to the movement of the lapping plate in relation to the workpiece, you slowly remove material.

Lapping can produce a dull grey matt finish or, with a diamond and Kemet composite process anything from a semi reflective finish to a mirror polish. For optical measurement using an optical flat or an interferometer, it is important that the surface is reflective. This is a big advantage for diamond lapping.

Lapping is a precision operation, so it takes quite a bit of time. To speed up the process, you can use a 2-stage operation. The first to remove material and create flatness and the second to produce a specific Ra value. This is only necessary when your target Ra is below 0.05µm and you need to remove a lot of material.

What is Polishing?

Polishing is often carried out after a lapping operation, to produce the ultimate in surface finish. Some of the common reasons for polishing are:-

- To produce mirror surfaces

- To improve appearances

- To obtain the optimum sealing surfaces

- To optically measure flatness

- To improve electrical contact

- To improve the optical qualities of materials

What is Conventional Lapping?

With conventional lapping the abrasive (aluminium oxide or silicon carbide) is applied in a carrying vehicle (Lapping Oil) onto a hard surface such as cast iron. The particles cannot be pressed into the surface and be secured there, so they roll and move freely in all directions. They hammer small particles out of the sample surface, introducing deep deformations. This takes place because the free moving abrasive particle is not able to produce a real scratch of the component surface. Instead, it hammers out small pockets. Because the light cannot reflect out of these pockets the resulting surface is always a matt grey.

What is Diamond Lapping?

Diamond lapping is a material removal method using fixed diamond abrasive particles which produce long chips of the component material. The process of making chips with a sharp abrasive grain produces the lowest amount of deformation in the component while giving the highest removal rate. Diamond abrasive is pushed into the lapping plate surface, by a chamfer on the leading edge of the conditioning rings. A reflective or (high) glossy result can be obtained by lapping on a composite lapping plate with a diamond emulsion. A finer grit size results in a lower roughness value.

What is Diamond Polishing?

Diamond Polishing uses the same mechanism as Diamond lapping. However, by using successively small grain sizes of 8, 6 and 3 micron diamond, with softer Kemet plates and polishing pads with higher resilience, polishing can remove the deformations and scratches from lapping.

What is Lapping?

What is Lubrication?

Sufficient lubrication between sample surface and the grinding/polishing surface is necessary because:

- Enhancement of cutting: The correct lubricant improves the cutting process and yields the smallest scratch depth and lowest deformation

- Reduce friction: The friction between the sample and the support must be correct; too little lubricant will cause over heating, too much lubricant will decrease the cutting action by washing away abrasive particles and creating aqua-planing condition.

- Cooling: The ideal conditions for optimal lapping/polishing will create frictional heat. This is kept low by using the correct lubricant

Why Choose Kemet Lapping Systems?

Kemet Flat Lapping and Polishing Systems offer the most efficient and reliable method of producing precision flat polished surfaces. Our flat lapping and polishing machines, and systems, are at the forefront of today's advanced lapping technology, especially when used with Kemet Diamond products.

Kemet Diamond quality and grading enables reliable precision lapping to be performed in production situations. Each Kemet Diamond product is a special blend of diamond powder with a specific grading and concentration in a chemical carrier to give optimum stock removal and surface finish, ease of cleaning, temperature resistance and lubricity to prevent drying out.

Kemet Diamond lapping generates less waste and is considered more environmentally friendly than conventional lapping methods.

Which Applications use Kemet Lapping Systems?

The range of industries using Kemet Flat Lapping systems is wide and varied:

| Aerospace | Pumps & Valves | Technical Ceramics | Tool and Die |

|---|---|---|---|

| Pumps & Valves | Fuel Pumps | Alumina - Zirconia | Mould and Inserts |

| Turbine Parts | Hydraulic Pumps | Silicon Carbide | Printing Plates |

| Engine Assemblies | Mechanical Seals | Piezo Ceramics | Slitter Knives |

| Spacers | Gate Valves | Ferrite | Extrusion Dies |

| Medical Devices | Data Storage | Electro optics | Automotive |

| Fibre Scopes | Disc Drive Heads | Plano Optics | Diesel Injectors |

| Surgical Instruments | Tape Heads | Laser Rods and Prisms | Piston Rings |

| Pacemaker Parts | CD Moulds | Fibre Optics | Fuel Pumps |

| Sensors |