Dual Face and Double Sided Precision Lapping and Polishing Systems

Kemet's sophisticated dual face processing equipment delivers exceptional performance for the simultaneous machining, lapping, and polishing of both surfaces on high-precision components. Engineered to handle an extensive variety of materials, these systems maintain remarkable accuracy and repeatability while achieving extremely stringent dimensional tolerances. Their gentle yet effective processing capability makes them ideal for handling sensitive and brittle materials, minimizing component stress and delivering outstanding surface finishes.

Consistent processing quality is ensured through an innovative five-carrier drive mechanism that provides uniform and stable material handling throughout each operation cycle. These machines incorporate adjustable plate and carrier rotational speeds managed through advanced AC frequency drive technology, enabling operators to optimize processing parameters for specific material requirements and desired outcomes.

To maximize operational efficiency, Kemet's Dual Face Systems include several advanced optional capabilities:

- Precision Thickness Control systems for accurate material removal and tight dimensional control

- Advanced Load Cell Force Management to maintain consistent processing pressure across all workpieces

- Sophisticated HMI Touch Screen Controls for streamlined operation, comprehensive process monitoring, and superior control functionality

These precision systems excel in demanding applications throughout multiple industries, including microelectronics, photonics, and specialized materials processing. They demonstrate exceptional performance when processing silicon and sapphire substrates, precision optical elements, specialized filter materials, luxury timepiece crystals, piezoelectric components, and critical storage device parts.

Kemet provides an extensive portfolio of lapping and polishing solutions engineered for diverse manufacturing needs. For unique processing challenges, Kemet develops and produces custom-engineered systems that deliver exceptional reliability and adaptability for specialized precision finishing applications.

Kemet DS 6, 9, 12 Series Featuring Analog Control Systems

| Technical Specifications | DS 6 | DS 9 | DS 12 |

|---|---|---|---|

| Lapping Plate Dimensions (mm) | Dia. 374 x Dia. 150mm | Dia. 645 x Dia. 235mm | Dia. 753 x Dia. 260mm |

| Maximum Component Diameter (mm) | Dia. 110mm | Dia. 180mm | Dia. 220mm |

| Carrier Pitch Circle Diameter (mm) | Dia. 139.3 (PCD) | Dia. 228.5 (PCD) | Dia. 283.6 (PCD) |

| Carrier Quantity | 5 Units | 5 Units | 5 Units |

| Minimum Component Thickness (mm) | 0.08mm | 0.3mm | 0.3mm |

| Lower Plate Rotation Speed (RPM) | 0 - 60 RPM | 0 - 60 RPM | 0 - 60 RPM |

| Carrier Direction Control | CW & CCW | CW & CCW | CW & CCW |

| Overall Dimensions (mm) | 930 (W) X 700 (L) X 1930 (H) | 1740 (W) X 1070 (L) X 2090 (H) | 1610 (W) X 1200 (L) X 2400 (H) |

| Approximate Weight | 800 KGS | 1800 KGS | 2300 KGS |

| Power Requirements | 380V / 415V 3Ph 50Hz | 380V / 415V 3Ph 50Hz | 380V / 415V 3Ph 50Hz |

Kemet DS 6, 9, 12 Series Featuring Advanced HMI Control

| Technical Specifications | DS 6 | DS 9 | DS 12 |

|---|---|---|---|

| Lapping Plate Dimensions | Dia. 374 x Dia. 150 mm | Dia. 630 x Dia. 240 mm | Dia. 753 x 260 mm |

| Maximum Component Diameter | Dia. 110 mm | Dia. 180 mm | Dia. 220 mm |

| Carrier Pitch Circle Diameter | Dia. 139.3 (PCD) | Dia. 228.5 (PCD) | Dia. 283.6 (PCD) |

| Carrier Quantity | 5 Units | 5 Units | 5 Units |

| Minimum Component Thickness | 0.08mm | 0.3mm | 0.3mm |

| Lower Plate Rotational Speed (RPM) | 0 - 60 RPM | 0 - 60 RPM | 0 - 60 RPM |

| Carrier Directional Control | CW & CCW | CW & CCW | CW & CCW |

| System Dimensions [mm] | 930 (W) X 700 (L) X 1930 (H) | 1480 (W) X 880 (L) X 2400 (H) | 1610 (W)X 1200 (L)X 2400 (H) |

| Approximate Weight | 800 kgs | 1800 kgs | 2300 kgs |

| Power Requirements | 380V / 415V 3Ph 50Hz | 380V / 415V 3Ph 50Hz | 380V / 415V 3Ph 50Hz |

Kemet DS 16, 18 Series Featuring Advanced HMI Control

| Technical Specifications | DS 16 | DS 18 |

|---|---|---|

| Lapping Plate Dimensions | Dia. 1155 x ID 360 mm | Dia. 1262 x ID 535 mm |

| Maximum Component Diameter | Dia. 390 mm | Dia. 390 mm |

| Carrier Pitch Circle Diameter | Dia. 423.33 (PCD) mm | Dia. 423.33 (PCD) mm |

| Carrier Quantity | 5 Units | 6 Units |

| Minimum Component Thickness | 0.3 mm | 0.3 mm |

| Lower Plate Rotational Speed (RPM) | 0 - 60 RPM | 0 - 60 RPM |

| Carrier Directional Control | CW & CCW | CW & CCW |

| System Dimensions [mm] | 2020 (W) x 1500 (L) x 2260 (H) | 2530 (W) x 1900 (L) x 2260 (H) |

| Approximate Weight | 6500 kgs | 7000 kgs |

| Power Requirements | 380V / 415V 3Ph 50Hz | 380V / 415V 3Ph 50Hz |

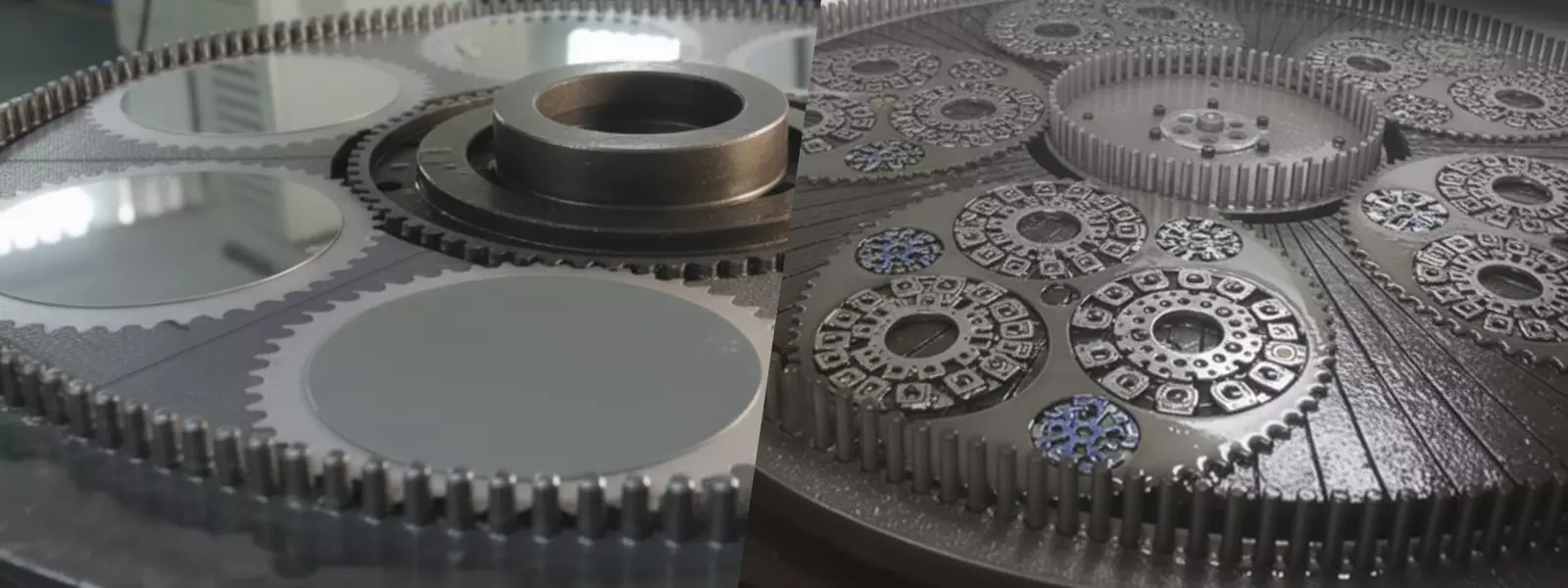

These Dual-Lap machines are based upon a two-way & three way planetary concept designed to yield very precise and repeatable results at an economical price. Excellent results have been obtained in the processing of a wide range of materials and components including glass, ceramics, crystals and ferrous materials. Only the Inner and Outer Gears rotate allowing the carriers to move around the surface of the plates, whilst the top and bottom plate stay stationary. The larger models use a 3- way system, where the top plate, bottom plate and sun gear rotate.

The Kemet Twin Lap M machine is a small but versatile bench mounted machine ideally suited for small workshops and laboratories for double sided lapping (Twin Lap L is a floor standing machine). It comes fully equipped and ready to use and is suitable for lapping components up to 114mm diameter and up to 30mm thick. In certain circumstances larger components can be accommodated.

The machine is belt driven and built on a Aluminium extrusion base. Machine feet eliminate vibration transfer to and from the floor. This design gives the operator a shorter reach to the plate and easy access underneath for maintenance. The main lap plate can rotate both directions, and the work holder will automatically oscillate.

The machine will operate with a free abrasive compound such as silicon carbide, alumina or boron carbide, suspended in a oil or water based vehicle or a Diamond Compound. The compound is fed onto the lap plate from a free-standing system via a peristaltic pump.

As with all double sided lapping machines, we recommend that the lap plates are re-conditioned using conditioning gears on a regular basis. The machine can also be fitted with diamond dispensing equipment and special complementary lap plates. Automatic thickness control is also an option.

The machines come fully equipped and ready to run. The controls are housed in a single steel console attached to the base frame at a convenient working height. In all cases the lapping operation is controlled by a multi range adjustable timer or optional DTI mode.

TwinLap M for components <51 mm dia x 20mm thick

TwinLap L for components <114 mm dia x 30mm thick

TwinLap XL for components <170 mm dia x 40mm thick

TwinLap L

TwinLap XL

| Technical Details | TwinLap M | TwinLap L | TwinLap XL |

|---|---|---|---|

| Dimensions L × W (mm) | 770 × 800 | 1000 × 800 | 1000 × 1130 |

| Capacity | Ø51mm OD max component size, 20mm thick max. Thickness +/- 0.005mm. Flatness <0.0005mm | Ø114mm OD max component size, 30mm thick max. Thickness +/- 0.005mm. Flatness <0.0005mm | Ø170mm OD max component size, 40mm thick max. Thickness +/- 0.005mm. Flatness <0.0005mm |

| Maximum plate force | 5kg | 20kg | 60kg |

| Outer ring gear speed | 0 - 111 rpm 60W DC drive | 0 - 20 rpm 300W DC drive | 0 - 30 rpm 300W DC drive |

| Inner sun gear speed | 0 - 125 rpm 60W DC drive | 0 - 40 rpm 300W DC drive | 0 - 50 rpm 300W DC drive |

| Aprox. Weight (kg) | 90 | 300 | 650 |

| Standard Tooling | 2 Cast iron lap plates Ø175mm, One set cast iron conditioning gears, One set top plate weights, One set work carriers | 2 Cast iron lap plates Ø370mm, One set cast iron conditioning gears, One set top plate weights, One set work carriers | |

| Optional Tooling |

| ||

| Optional Features |

| ||

| Electrical supply | 240V-single phase-50Hz or 110V-single phase-60Hz | 480V-3 Phase-50Hz or 380V-single phase-60Hz | |

| Product code | 359314 | ||