Diamond Abrasive Products

Kemet International is a leading provider of diamond-based solutions, specialising in precision lapping and surface finishing across various industrial domains. Our expertise lies in shaping and grading diamond particles for superior results. To ensure precision in surface finishing, we employ a refined sedimentation process and utilise microscopic and computer shape analysis to grade our diamond powder. This meticulous approach results in an exceptionally tight distribution curve, eliminating irregularly sized diamond particles that could compromise the surface finish. Instead, our carefully selected diamond particles match in size and shape, maximising efficiency and delivering exceptional results.

Our Diamond Powders encompass Monocrystalline and Polycrystalline powders, providing enhanced versatility. Additionally, our Diamond Paste/Compounds, available in Oil-Based and Water-Based forms, further enhance precision surface finishing. The diamond abrasives offered by Kemet International boast uniform crystal structures, ensuring consistent performance and precision. This characteristic is particularly valuable in critical applications, such as the semiconductor industry, where intricate work is essential. The diamonds' ability to maintain a sharp cutting edge even under intense pressure ensures high-quality results without compromise.

At Kemet International, our dedication to excellence and extensive array of diamond abrasive products create exciting opportunities for achieving precision surface finishing in diverse industries.

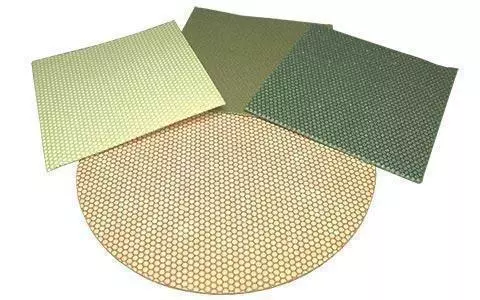

Diamond Plated/Coated and Impregnated Products

Diamond-coated and diamond-impregnated products offer a host of compelling benefits across diverse industries. The key advantage of diamond-coated products lies in their exceptional hardness and durability, enabling them to perform cutting, drilling, and grinding tasks with remarkable precision and longevity. These coatings resist wear and abrasion, reducing maintenance and replacement costs. On the other hand, diamond-impregnated products combine the hardness of diamonds with the structural integrity of the base material, offering enhanced performance in specialised applications like concrete drilling and stone cutting. The diamond particles embedded in the material ensure consistent and efficient performance over prolonged use. Both types of products deliver unparallelled thermal conductivity, preventing overheating during high-speed operations and improving overall efficiency. Whether it's in manufacturing, construction, or electronics, the utilisation of diamond-coated and diamond-impregnated products elevates productivity, extends equipment lifespan, and guarantees superior results, making them invaluable assets for industries seeking cutting-edge performance.

Diamond Abrasives in Dentistry

In dentistry, dental restorations like dentures and dental crowns are vital for restoring teeth function and appearance. However, achieving a polished finish on these restorations is challenging, requiring specialised tools and materials.

This specialised diamond abrasive paste for the dental market contains microfine crystalline diamond particles that effectively achieve a polished finish. Evenly distributed, it ensures consistent results on different restorations. Its firm consistency allows precise application with brushes and felts, minimising accidental smudging or over-application. Manufactured to ISO 9001:2015 Quality Assurance standards, it meets strict quality control requirements and is consistently reliable.

Note that the diamond polishing paste is not for oral use; it is intended for dental technicians and laboratories, and should be handled with care to avoid ingestion or contact with mucous membranes.