Machining & Tooling Marks Removal

CNC machining is a highly precise and efficient manufacturing process that is widely used in various industries. However, one of the challenges that CNC machining faces is the occurrence of tool marks on the machined surface. Tool marks can result in a rough surface finish, which can be aesthetically unpleasing and may impact the functionality of the component.

Removing or preventing tool marks is crucial in achieving a high-quality surface finish. Fortunately, XEBEC Brush™ provides an innovative solution to remove tool marks and achieve a smooth surface finish. The XEBEC Brush™ uses abrasive ceramic fibre material instead of abrasive grain. Each bristle consists of 500 -1,000 ceramic fibres that work as cutting edges, providing excellent cutting ability.

The XEBEC ceramic fibre has three features that make it effective for CNC deburring and polishing. Firstly, the uniquely developed ceramic fibres are the abrasives, and its fibre content ratio is over 80%. The cutting edges that are made up of the tip of each fibre bristle create an overwhelming grinding power. The XEBEC Brush™ has 60 times higher grinding power compared to nylon brushes and steadily removes burrs.

Secondly, due to the structure of XEBEC ceramic fibre, new cutting edges are always exposed. This feature ensures that the brush maintains consistent cutting performance to the end, enabling CNC deburring and polishing.

Finally, the XEBEC Brush™ maintains its straight shape and does not spread out like a toothbrush, even after repeated use. This feature makes it ideal for CNC deburring and polishing in mass production lines.

In addition to removing tool marks, the XEBEC Brush™ can also improve the surface finish of the machined component. The brush can achieve a surface finish of Ra 0.1μm or less, which is ideal for components that require a high level of precision and smoothness.

The XEBEC Brush™ is an innovative solution for removing tool marks and achieving a smooth surface finish in CNC machining. Its unique ceramic fibre material and features make it an effective and efficient tool for mass production lines. With the XEBEC Brush™, manufacturers can improve the quality of their components and reduce production costs.

XEBEC Brush™ Surface End Type

Ideal for machining mark removal and polishing sealed surface

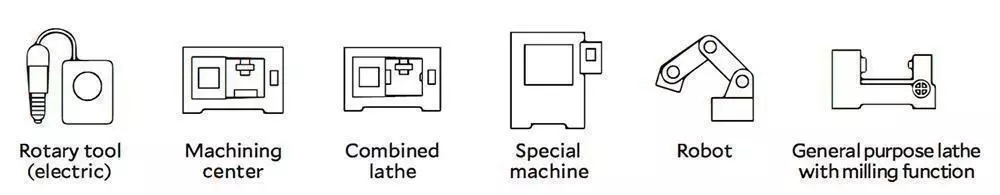

Applicable Equipment

The tool can be used with rotary tools and equipments that can control the rotational speed.

| Brush (Colour) | Product code | Brush diameter (mm) | Shank diameter (Dc) (mm) | Bristle length (l) (mm) | Overall length (L) (mm) | Recommended rotational speed (min-1) | Maximum rotational speed (min-1) |

|---|---|---|---|---|---|---|---|

| A13 (Pink) | A13-EB01S | 1 | 3 | 15 | 52 | 7000-12000 | 15000 |

| A13-EB015S | 1.5 | 3 | 15 | 52 | 7000-12000 | 15000 | |

| A13-EB02S | 2 | 3 | 15 | 52 | 7000-12000 | 15000 | |

| A13-EB025S | 2.5 | 3 | 15 | 52 | 7000-12000 | 15000 | |

| A13-EB03M | 3 | 3 | 30 | 67 | 4000 | 6000 | |

| All (Red) | A11-EB01S | 1 | 3 | 15 | 52 | 7000-12000 | 15000 |

| A11-EB015S | 1.5 | 3 | 15 | 52 | 7000-12000 | 15000 | |

| A11-EB02S | 2 | 3 | 15 | 52 | 7000-12000 | 15000 | |

| A11-EB025S | 2.5 | 3 | 15 | 52 | 7000-12000 | 15000 | |

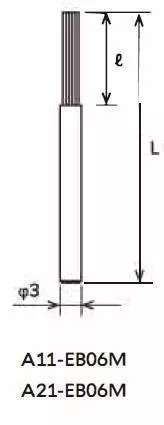

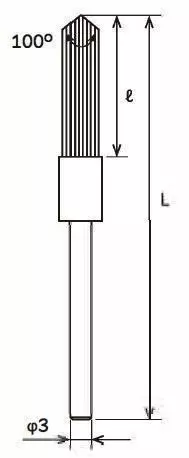

| A11-EB06M | 5 | 3 | 20 | 57 | 7000 | 12000 | |

| A21 (White) | A21-EB06M | 5 | 3 | 20 | 57 | 7000 | 12000 |

| A32 (Blue) | A32-EB06M | 5 | 3 | 20 | 57 | 7000 | 12000 |

* The Brush size is approximate as the tip expands by rotating.

Precautions for Use For manual operation, do not exceed the maximum load of 2N. The Brush will break off when:

- being used beyond the maximum rotational speed

- being used beyond the maximum load

- being used with a pneumatic tool

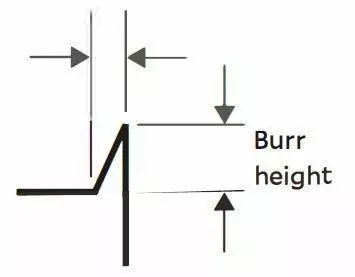

Target burr size

Burr root thickness of 0.1mm or less (Burrs are easily bent with a fingernail)

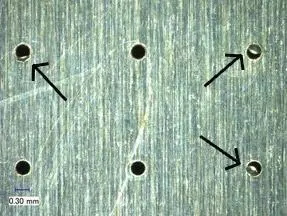

Case Study: Precision / Deburring smaller holes

Material: Aluminum Alloy

Pre-Processing: Drilling process

Description: Ø0.3mm Drilling process

Tool Used: A13-EB03M (XEBEC Cutting Fiber)

Revolution: 1500min-1

Feed: 1200mm/min

Depth of Cut : 1.0mm

Before Deburring smaller holes

After Deburring smaller holes