Deburring Threads and Cross Holes on CNC Lathe - XEBEC Brush™ Turning

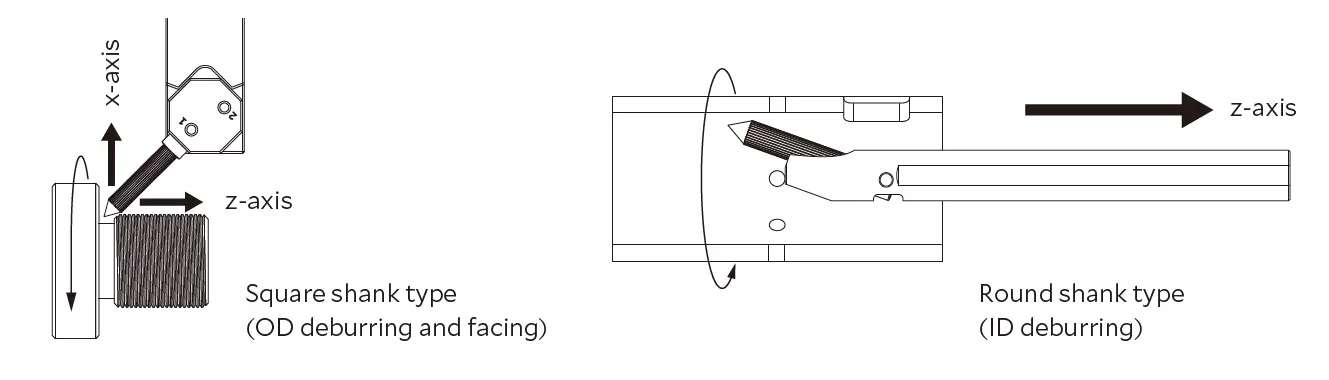

Round and Square Shank Types for ID and OD Deburring

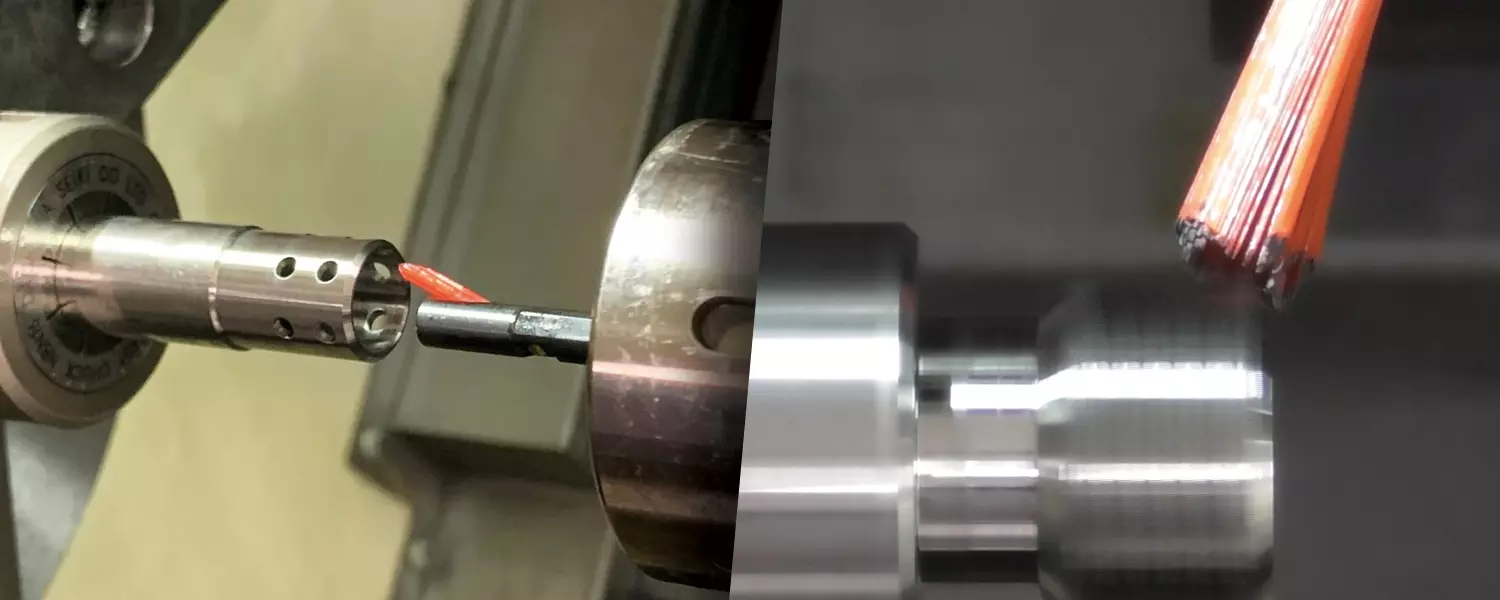

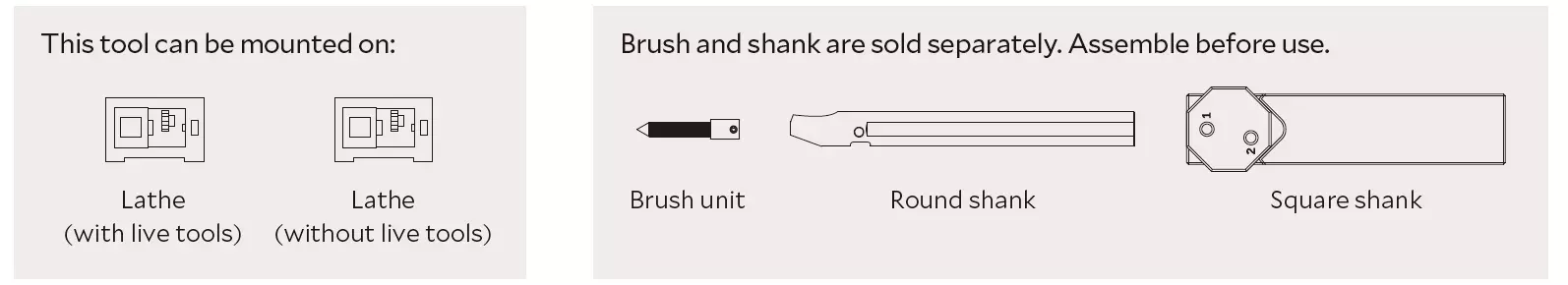

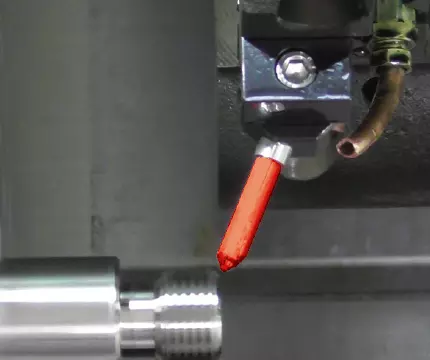

XEBEC Brush™ Turning is the first practical application of ceramic fiber brushes for deburring on CNC lathes. It is mounted on the turret and used alongside other static tools. Removing burrs on the same machine as facing and turning operations realises important time and cost savings. It also eliminates the variable quality and danger inherent to manual deburring, particularly when the operator has to reach into the machine to deburr by hand.

Key Features

- Automated deburring on CNC lathes: Tested and proven in various production environments, from job shops to mass production plants

- Ideal for: Removing micro burrs under 0.01 mm and fine burrs no thicker than 0.1 mm

- Available in: Three grit equivalents (red, white, blue), two sizes (φ2.5 mm and φ6 mm), and two shapes (tapered and flat)

- Typical applications: Crosshole deburring (ID and OD), thread deburring, and groove polishing

Deburring of Multiple Crossholes

The round shank version (A11-TB025 + TM-SH-06) is 11 mm high, enabling 12 mm bores and ID threads to be deburred. The flexible fibers of the brush deburr multiple crossholes as they are pulled out of a bore. The small brush (φ2.5 mm) can negotiate crossholes up to 3 mm in diameter. The large brush (φ6 mm) can be used to deburr any size crosshole. Running the spindle clockwise and then counter clockwise results in even deburring of crossholes.

Adjustable Brush Angle

The brush angle of the square shank type is adjustable to optimise the deburring action, whereas the brush angle of round shank type is fixed at a shallow angle. The advantage of shallow angles (closer to horizontal) is that they allow the flexible fibers to deburr discontinuous surfaces such as crossholes. The square shank type also enables steep brush angles (near perpendicular). This concentrates the grinding power of the ceramic fibers in the tip of the brush, making it ideal for thread deburring.

Specification

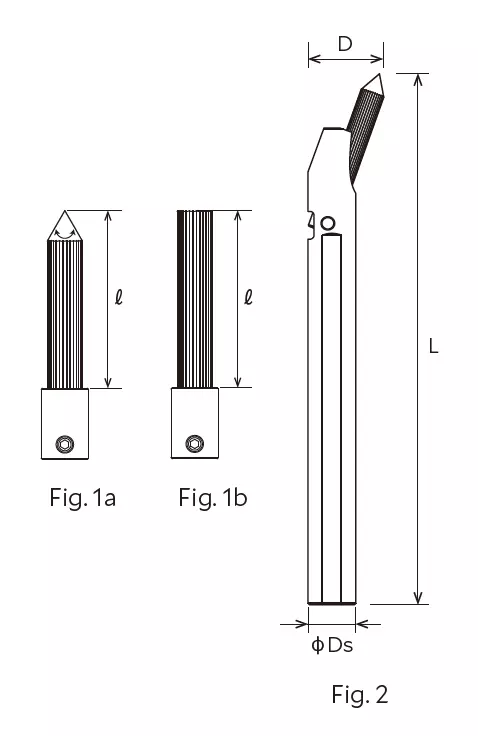

Brushes

| Brush (Color) | Product Code | Brush Diameter (mm) | Brush Length ℓ (mm) | Matching Holder | Fig. |

|---|---|---|---|---|---|

| A11 (red) | A11-TB025 | φ2.5 | 15 | TM-SH-06 | 1a |

| A11-TB06 | φ6 | 30 | TM-SH-S2020, TM-SH-S2525, TM-SH-12 | 1a | |

| A11-CB06M | φ6 | 30 | TM-SH-S2020, TM-SH-S2525 | 1b | |

| A21 (white) | A21-TB06 | φ6 | 30 | TM-SH-S2020, TM-SH-S2525, TM-SH-12 | 1b |

| A21-CB06M | φ6 | 30 | TM-SH-S2020, TM-SH-S2525 | 1b | |

| A32 (blue) | A32-TB06 | φ6 | 30 | TM-SH-S2020, TM-SH-S2525, TM-SH-12 | 1b |

| A32-CB06M | φ6 | 30 | TM-SH-S2020, TM-SH-S2525 | 1b |

Note: Holders must be at least 30 mm inside tool blocks and securely fastened.

Round Shanks

| Product Code | Length L (mm) | Shank Dia. Ds (mm) | Bore Size D (mm) | Cutting Dia. (mm) | Max. Side Hole (mm) | Matching Brush | Fig. |

|---|---|---|---|---|---|---|---|

| TM-SH-06 | 107 | φ6 | ≥11 | ≥φ12 | <φ3 | A11-TB025 | 2 |

| TM-SH-12 | 133 | φ12 | ≥20 | ≥φ21 | No limit | A11-TB06, A21-TB06, A32-TB06 | 2 |

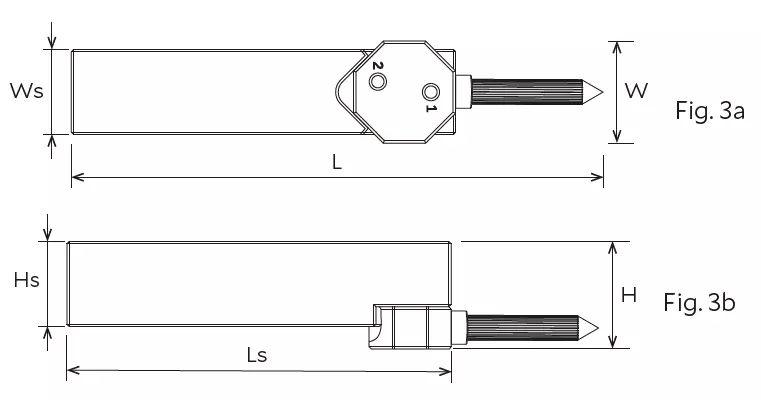

Square Shanks

| Product Code | Length L (mm) | Shank Height Hs (mm) | Height H (mm) | Shank Width Ws (mm) | Width W (mm) | Shank Length Ls (mm) | Matching Brush |

|---|---|---|---|---|---|---|---|

| TM-SH-S2020 | 124 | 20 | 26 | 20 | 24 | 90 | A11-TB06, A21-TB06, A32-TB06, A11-CB06M, A21-CB06M, A32-CB06M |

| TM-SH-S2525 | 134 | 25 | 31 | 25 | 24 | 100 | A11-TB06, A21-TB06, A32-TB06, A11-CB06M, A21-CB06M, A32-CB06M |

Tool Selection

Brush Selection

| Burr Size | Micro Fine Burrs (Burr thickness ≤ 0.1 mm) | ||

|---|---|---|---|

| Brush (Color) | A11 (red) | A21 (white) | A32 (blue) |

| Grinding Power | High | → | → |

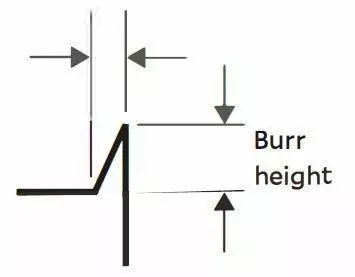

Note: Micro fine burrs have a burr height ≤ 0.01 mm.

Holder Selection

| Process | Holder | Brush Angle |

|---|---|---|

| Crosshole deburring | XEBEC Brush Turning Round Shank | Fixed |

| Thread deburring - ID threads | XEBEC Brush Turning Round Shank | Fixed |

| Thread deburring - OD threads | XEBEC Brush Turning Square Shank | Set by user |

Applicable Burr Size

Maximum burr thickness is 0.1 mm. Burrs this size can be easily bent by fingernail.

How to Use

Pull the Brush, Do Not Push

This is a specialist pull turning and facing tool. Pulling the brush reduces bristle deflection and negotiates discontinuous geometries such as crossholes. The bristles will break if the brush is pushed. The tool must be pulled in the x-axis away from the main spindle when facing and pulled in the z-axis away from the main spindle when ID or OD deburring.

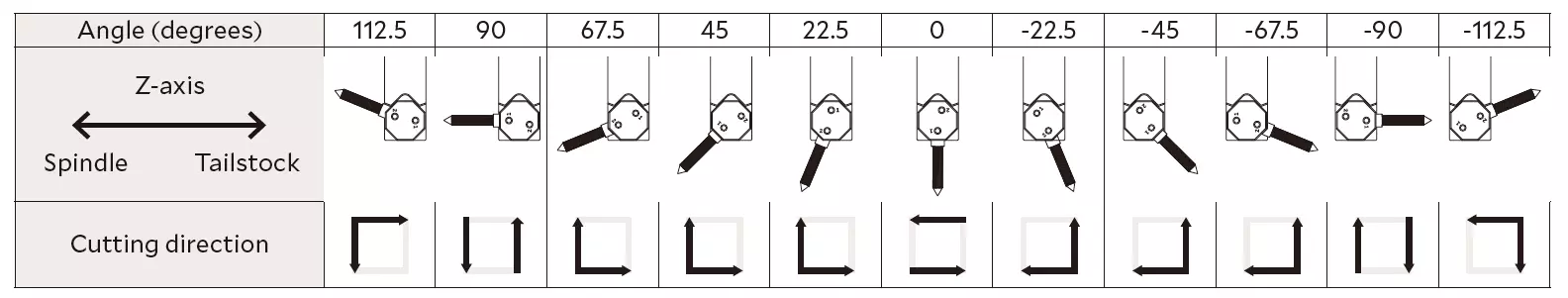

Brush Angle (Square Shank)

The square shank has eleven different angles to match the deburring edge. Arrows indicate permissible cutting direction.

Depth of Cut (Round Shank)

The brush angle of XEBEC Brush Turning Round Shank is fixed at 20 degrees. Maximum depth of cut is 2.0 mm. Usable bristle length varies with the brush diameter.

| Brush Diameter (mm) | Brush Angle | Max. Usable Bristle Length |

|---|---|---|

| φ2.5 (TB025) | 20 deg. (Fixed) | 3.0 mm |

| φ6 (TB06) | 20 deg. (Fixed) | 5.5 mm |

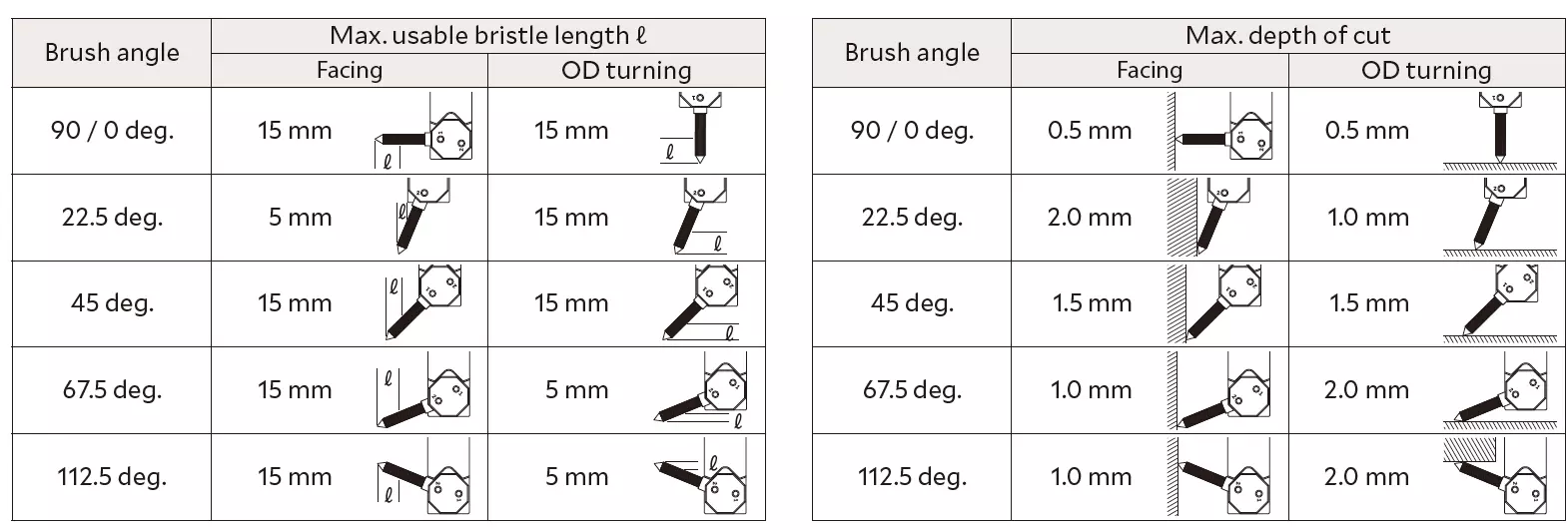

Depth of Cut (Square Shank)

The usable bristle length and maximum depth of cut of the square shank vary with the brush angle. Depth of cut is no more than 2.0 mm.

Maximum Usable Bristle Length

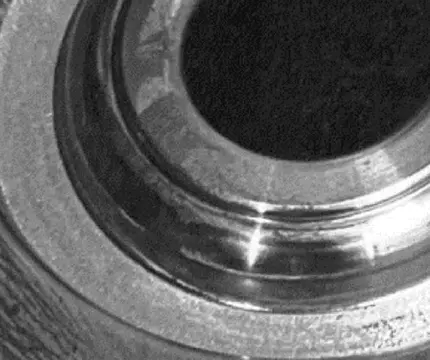

Crosshole Deburring Mechanism (Round Shank)

A shallow brush angle and large depth of cut are required to remove burrs on crossholes. The pressure exerted on the brush pushes it into a crosshole, with its tapered tip scraping off burrs as the brush is pulled back and out of the hole. If cycle time permits, the workpiece should be rotated both clockwise (CW) and counter-clockwise (CCW) for uniform edge quality.

The maximum crosshole size for the small brush (A11-TB025) is φ3 mm. The bristles of the small brush are stiffer than the larger brush because they are only half the length. This limits the size of crosshole which can be deburred. The large brush (A11-TB06) has no crosshole size restriction.

External Thread Deburring Mechanism (Square Shank)

A steep brush angle is required to remove burrs on an external thread. The recommended brush angle for deburring the crests is 22.5 degrees. This concentrates most of the grinding power in the tip of the brush, while preventing bristles from being deflected on either side of a crest.

The workpiece should be rotated clockwise (CW) for a right-hand thread and counter-clockwise (CCW) for a left-hand thread. If the correct rotational direction and brush angle (22.5 deg.) are used, the brush can be pulled easily along the thread.

| Shank Type | Target Edges | Brush Type | Brush Angle |

|---|---|---|---|

| Square shank | Full thread (incl. start and end) | TB06 (Turning) | 22.5 deg. |

| Thread (incl. start) | TB06 (Turning) | 22.5 deg. | |

| Thread (start only) | CB06 (Chamfer) | 45 deg. |

Application Examples

Crosshole Deburring

Workpiece material: Carbon steel

Main bore diameter: Outer 16 mm, Inner 12 mm

Crosshole diameter: 3 mm

| Brush (Color) | Holder | Angle (deg.) | Depth of Cut (mm) | Cutting Speed (m/min) | Feed Rate (mm/rev) | Rotational Direction |

|---|---|---|---|---|---|---|

| A11-TB025 (red) | TM-SH-06 | 20 (Fixed) | 1.5 | 150 | 0.1 | CW + CCW |

Thread Deburring

Workpiece material: Stainless steel

Thread size: 24 x 2 mm

| Brush (Color) | Holder | Angle (deg.) | Depth of Cut (mm) | Cutting Speed (m/min) | Feed Rate (mm/rev) | Rotational Direction |

|---|---|---|---|---|---|---|

| A32-TB06 (blue) | TM-SH-S2020 | 22.5 | 0.5 | 150 | 0.1 | CW |

Groove Polishing

Workpiece material: YXR3 (HRC 60)

| Brush (Color) | Holder | Angle (deg.) | Depth of Cut (mm) | Spindle Speed (min⁻¹) |

|---|---|---|---|---|

| A32-CB06M (blue) | TM-SH-2020 | 90 | 1.0 | 720 |