Vapour Degreasing Alternative

The Evolution of Vapour Degreasing

Traditional vapour degreasing has long been a trusted method for removing oils, greases, and contaminants from precision components. However, modern manufacturing demands safer, more efficient alternatives that deliver superior results while protecting both workers and the environment.

Kemet now offers vacuum solvent cleaning machines - the next generation in degreasing technology. These advanced systems provide all the cleaning power of traditional vapour degreasing whilst offering significant improvements in safety, efficiency, and environmental performance.

Why Upgrade from Traditional Vapour Degreasing?

Enhanced Safety Features

Traditional vapour degreasing systems, particularly those using solvents like trichloroethylene (TCE), posed significant health and safety concerns...

- No Harmful Vapour Exposure: Operating under complete vacuum conditions means no hazardous solvent vapours released into the workplace

- Non-ATEX Requirements: Uses modified alcohols with flash points above 60°C

- Safer Working Environment: Absence of spills or harmful exhalations

- Lower Toxicity: Modern modified alcohols have minimal toxicity

Superior Environmental Performance

Environmental concerns have driven the phase-out of traditional vapour degreasing solvents...

- 99% Solvent Recovery: Advanced distillation technology

- Low Global Warming Potential (GWP): Modified alcohols have negligible impact

- No Ozone Depletion: Eliminates harmful substances

- Circular Economy Model: Recovered oils and particles reused

Enhanced Cleaning Performance

Vacuum solvent cleaning technology doesn't just match traditional vapour degreasing - it surpasses it:

- Better Penetration: Low surface tension reaches blind holes

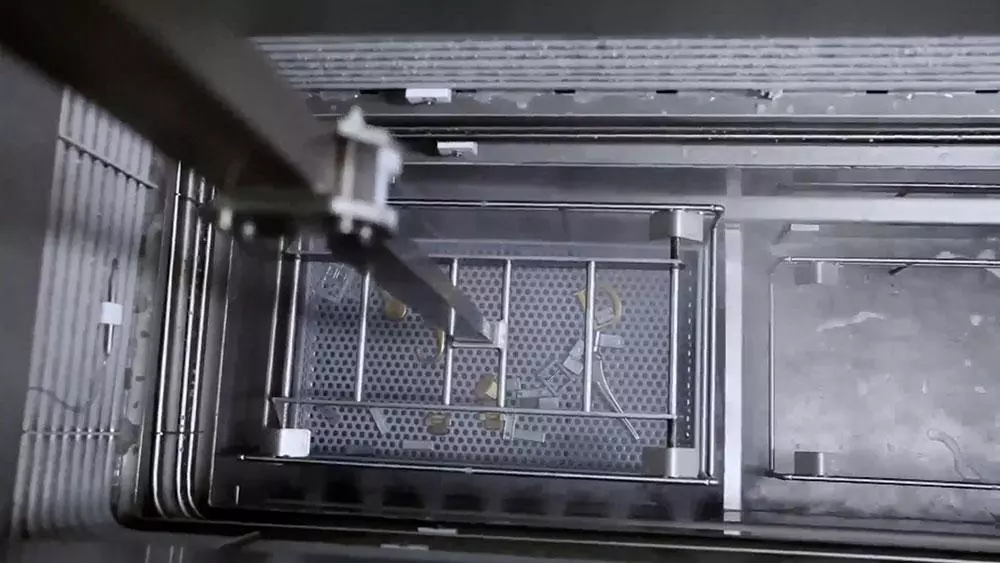

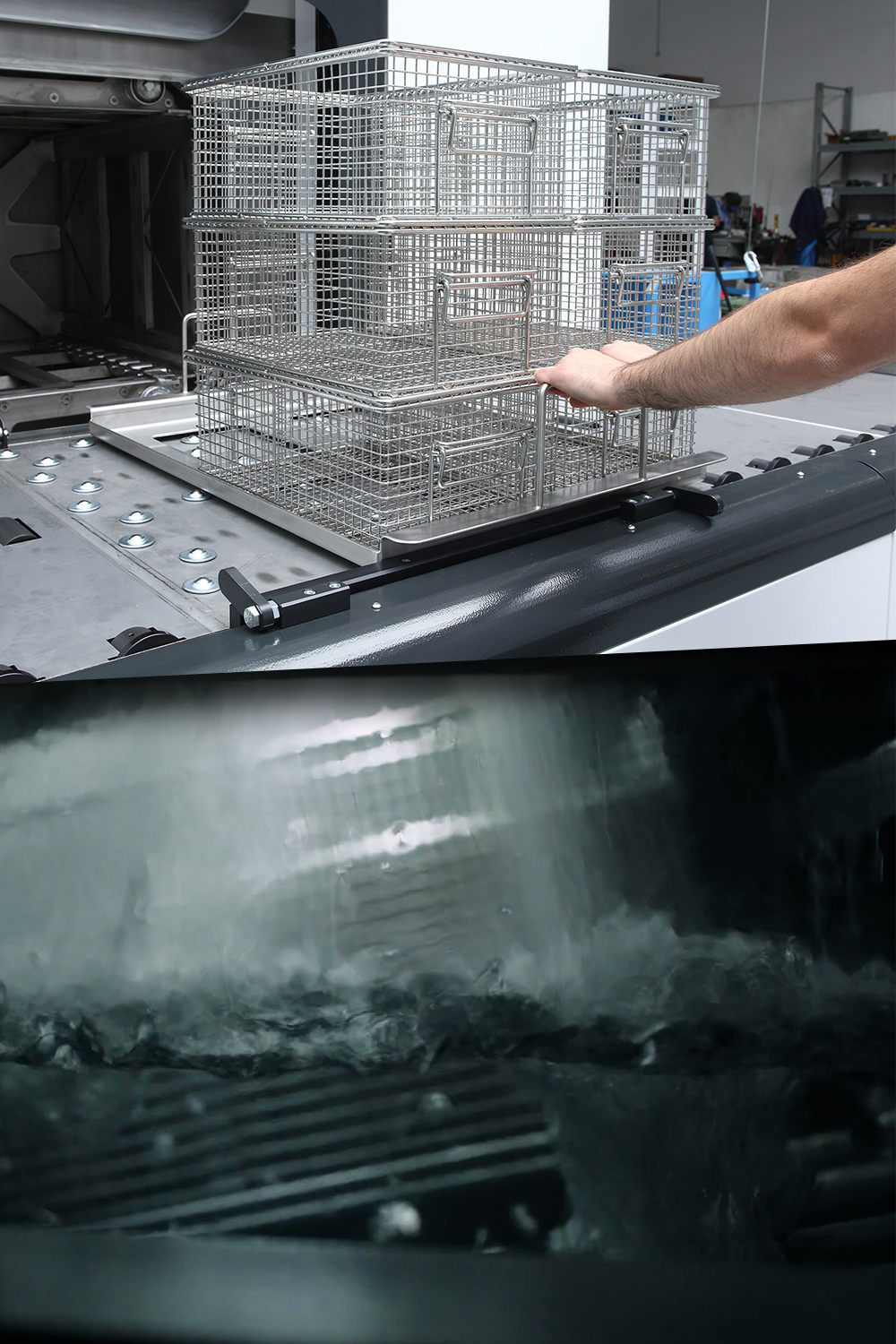

- Multi-Stage Process: Spray cleaning, ultrasonics, vacuum drying

- Continuous Filtration: Maintains solvent purity

- Programmable Cycles: Touchscreen customisation

Significant Cost Savings

Modern vacuum solvent cleaning delivers impressive operational savings:

- Minimal Solvent Loss: Reduces costs up to 50%

- Lower Energy Consumption: Less heating required

- Reduced Maintenance: Remote diagnostics minimise downtime

- Material Recovery: Distillation separates oils and swarf

Understanding Vacuum Solvent Cleaning Technology

How It Works

Vacuum solvent cleaning operates entirely under vacuum (down to 1 millibar), creating optimal conditions for thorough decontamination:

- Pre-Wash Phase: Components are sprayed with modified alcohol whilst the basket rotates, removing bulk contamination

- Ultrasonic Cleaning: Immersion in clean solvent with ultrasonic agitation penetrates microscopic crevices and removes stubborn residues

- Rinse Cycle: Fresh solvent rinse removes any remaining contaminants

- Vacuum Drying: Under vacuum, solvent evaporates rapidly at low temperatures, leaving components completely dry

- Distillation: Used solvent is continuously distilled and purified for reuse, whilst contaminants are filtered out

The Modified Alcohol Advantage

Modern modified alcohols offer the ideal balance of cleaning power and safety:

- Flash points exceeding 60°C eliminate fire hazards

- Excellent solvency for oils, greases, polishing compounds, and lapping pastes

- Compatible with all common materials including aluminium, brass, stainless steel, and plastics

- Low environmental impact with straightforward handling and disposal

Applications: From Precision to Production

Vacuum solvent cleaning excels across diverse industries:

- Precision Mechanics: Removes all traces of machining oils from tight-tolerance components

- Automotive: Degreases engine parts, transmission components, and fuel system elements

- Medical & Dental: Provides contamination-free surfaces for implants and instruments

- Aerospace: Meets stringent cleanliness standards for critical components

- Jewellery & Watches: Gentle yet effective cleaning of delicate items

- Electronics: Removes flux residues and manufacturing contaminants

- Mould Making: Cleans complex mould inserts and dies thoroughly

Technical Advantages Over Traditional Vapour Degreasing

Temperature Control

Traditional vapour degreasing relies on boiling solvents at 40-45°C. Vacuum solvent cleaning operates at even lower temperatures under vacuum conditions, making it safer for thermally sensitive components whilst achieving faster drying.

Solvent Management

Conventional systems lose significant solvent through evaporation and dragout. Our vacuum machines recover 99% of solvent through continuous distillation, with closed-loop operation minimising losses and environmental impact.

Process Monitoring

Modern touchscreen controls and remote diagnostics via Ethernet provide real-time monitoring, predictive maintenance alerts, and production data logging - capabilities impossible with traditional vapour degreasers.

Automation Options

Manual and automatic loading platforms accommodate different production scales. Automated systems can manage multiple washing stations with customised cycles, integrating seamlessly into modern manufacturing workflows.

Making the Transition

Switching from traditional vapour degreasing to vacuum solvent cleaning is straightforward:

Assessment: Kemet's technical team evaluates your current degreasing requirements, component types, and production volumes

Machine Selection: We recommend the optimal system from our range based on your specific needs

Installation: Complete turnkey installation includes commissioning, operator training, and method development

Support: Remote diagnostics and technical support ensure ongoing optimal performance

The Future of Industrial Degreasing

As environmental regulations tighten and workplace safety standards rise, traditional vapour degreasing continues its decline. Vacuum solvent cleaning represents the proven, practical alternative that delivers superior results whilst protecting people and the planet.

Kemet's range of vacuum solvent cleaning machines offers the perfect solution for businesses seeking a modern vapour degreasing alternative. With models from compact 30kg units to industrial 800kg systems, we provide the technology to meet any degreasing challenge.

Ready to Upgrade?

Contact Kemet today to discuss how vacuum solvent cleaning can transform your degreasing operations. Our technical specialists will help you select the ideal system and develop a transition plan that maintains production whilst improving safety, efficiency, and environmental performance.

Discover why leading manufacturers across precision mechanics, automotive, medical, and aerospace sectors have made vacuum solvent cleaning their vapour degreasing alternative of choice.

Frequently Asked Questions

Can vacuum solvent cleaning handle the same components as vapour degreasing?

Yes, and more. The low surface tension and ultrasonic capabilities actually improve cleaning of complex geometries, blind holes, and porous materials that challenged traditional systems.

What about drying times?

Vacuum drying is significantly faster than traditional methods. Components emerge completely dry and ready for immediate use, with typical cycle times of 3-6 hours including full cleaning.

Are there limitations on materials?

Vacuum solvent cleaning works with all materials suitable for traditional vapour degreasing, plus many plastics and composites that were problematic with older solvents.

How does the cost compare?

Initial investment is comparable to traditional vapour degreasing equipment, but operational costs are dramatically lower due to solvent recovery, reduced energy consumption, and minimal maintenance.

What about regulatory compliance?

Vacuum solvent cleaning systems meet all current environmental and workplace safety regulations. Modified alcohols eliminate the regulatory concerns associated with TCE and other phased-out solvents.

What is Vapour Degreasing?

Vapour degreasing is a process that uses a solvent in a closed chamber to create a vapour that dissolves contaminants on metal and plastic parts. The solvent is heated to its boiling point, and the vapour created rises and condenses on the parts being cleaned, dissolving the contaminants. The process is used in a variety of industries, including aerospace, automotive, and electronics, to clean precision components.

How Does Vapour Degreasing Work

The vapour degreasing process involves four main steps: solvent selection, heating, vapourisation, and condensation. The solvent used in the vapour degreasing process must be chosen carefully based on the type of contaminants present on the parts being cleaned. Solvents such as trichloroethylene, perchloroethylene, and methylene chloride are commonly used for degreasing applications because of their low boiling points and high solvency power. Once the solvent is chosen, it is heated to its boiling point. Heating the solvent causes it to evaporate and rise into the degreasing chamber. The heated solvent rises into the degreasing chamber and forms a vapour. The solvent vapour envelops the parts being cleaned, and the vapours penetrate into every crevice and contour of the parts. After the vapours have penetrated the parts, they begin to cool down and condense. As they condense, the solvents dissolve the contaminants on the parts and become heavier. The condensed solvent droplets then drip off the parts and collect at the bottom of the degreasing chamber, where they are drained and filtered for reuse.

Vapour degreasing offers several advantages over other cleaning methods. Some of the benefits include: High cleaning efficiency: Vapour degreasing can remove a wide range of contaminants, including oil, grease, wax, and flux residues. The process is also effective in removing complex geometries and hard-to-reach areas. No water required: Unlike aqueous cleaning methods, vapour degreasing does not require water, which can lead to oxidation and rust formation on metal parts. Low solvent consumption: Vapour degreasing is a closed-loop process, which means that the solvent is constantly recycled and reused. This reduces the amount of solvent used, making it a cost-effective and environmentally friendly cleaning method.

Although vapour degreasing is an effective cleaning process, it can be hazardous if proper safety measures are not taken. Some of the safety measures that need to be considered include: Proper ventilation: The degreasing chamber must be equipped with adequate ventilation to prevent the accumulation of solvent vapours, which can be harmful to workers. Personal protective equipment: Workers must wear appropriate personal protective equipment, including gloves, goggles, and respiratory protection, when working with solvents. Proper handling and storage: Solvents should be handled and stored in accordance with the manufacturer's instructions. This includes proper labelling, storage, and disposal.

Vapour Degreasing in Trichloroethylene

Trichloroethylene (TCE) is a clear, colourless liquid with a sweet odour that was widely used as a solvent for vapour degreasing in various industries. However, TCE has been phased out for this purpose due to its harmful effects on human health and the environment.

One of the primary reasons why TCE is no longer used for vapour degreasing is its potential to cause serious health problems. Exposure to TCE can result in skin irritation, dizziness, headaches, and nausea. Furthermore, TCE has been linked to more serious health issues such as cancer and damage to the liver, kidneys, and nervous system. The Occupational Safety and Health Administration (OSHA) has set a permissible exposure limit (PEL) of 50 parts per million (ppm) for TCE, which is considered to be a dangerous level of exposure.

In addition to its harmful effects on human health, TCE also poses a significant risk to the environment. TCE is a volatile organic compound (VOC) that can easily evaporate into the air, leading to the formation of ground-level ozone and smog. TCE can also contaminate groundwater and soil, which can have long-term effects on the ecosystem.

To address these concerns, the United States Environmental Protection Agency (EPA) has established regulations to phase out the use of TCE for vapour degreasing. The EPA has identified several safer alternatives to TCE, including modified alcohols, hydrofluoroethers, and other non-flammable solvents.

Modified alcohols are one of the most commonly used alternatives to TCE. These solvents are generally safer for human health and the environment and are effective at removing oils, greases, and other contaminants from metal parts. Hydrofluoroethers are another alternative that has been gaining popularity in recent years. These solvents have a low boiling point, making them ideal for vapour degreasing, and are not classified as VOCs, making them safer for the environment.