The Ultimate Blind Hole Ultrasonic Cleaner

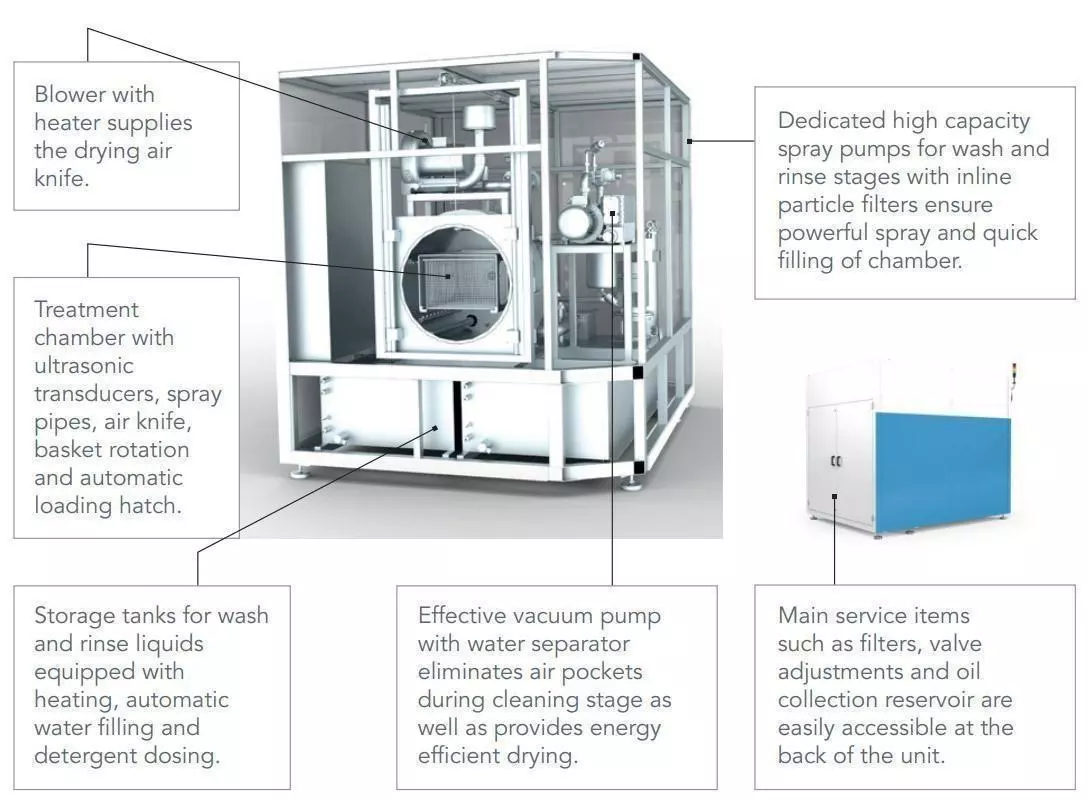

The Sonett is a single chamber cleaning unit with automatic wash - rinse - dry cycle. It cleans particles and soluble contaminants from components with aqueous media utilizing spray, immersion, ultrasonic, basket rotation, hot air and vacuum techniques. The combination of the cleaning techniques provides unique benefits when cleaning e.g. bulk materials or components with complex geometries with blind holes and small clearances.

Unique features and benefits

- High cleanliness levels on complex geometries thanks to diversity/ comprehensive array of cleaning techniques.

- Ease of use and reduced labor input thanks to automatic multistage cleaning cycle.

- Energy efficient process thanks to closed chambers and thermal insulation of tanks and vessels.

- Basket rotation

- Full coverage and even distribution of spray and ultrasonic cleaning effect thanks to basket rotation on the horizontal axis.

- Good contact of cleaning media with parts by eliminating air pockets and minimizes drag over between stages by effective draining of the parts.

- Vacuum

- Vacuum can be applied during cleaning for eliminating air pockets and ensuring wash liquid intrusion into blind holes and small clearances.

- Combination of hot air knife and vacuum provides highly capable and energy efficient drying.

Key applications

- Applications: Degreasing, particle cleaning

- Industries: machinery, automotive, metal products manufacturing

- Components: Bulk materials, components with complex geometry e.g. blind holes, internal channels, small clearances that benefit from vacuum and/or rotation.

Process stages and functions available for user programmable automated cleaning cycles:

- Washing with liquid from storage tank 1

- Rinsing with liquid from storage tank 2 Both with:

- Spray in air

- Ultrasonic with immersion

- Spray under immersion

- Drying

- Blowing with hot air knife

- Vacuum drying

- Cycle repetition (hot air – vacuum) available

- Basket rotation or tilting is available for all process stages.

- Vacuum can be applied during immersion wash and rinse stages.

Complementing options

Electro polished wash baskets with a range of mesh sizes and lid designs to hold washed parts.

- Safety bund for added security.

- Pump enabling drainage of storage tanks to external containers.

- Oil separator also for rinsing stage to remove any drag over oils.

- Automatic purge for rinsing stage to maintain consistent rinsing results.

- Additional rinsing stage with fresh water for residue free rinsing results.

- Additional rinsing stage with storage tank for upgraded cleaning results and reduced rinse water consumption.

| Technical data - Sonett 300 | |

|---|---|

| Wash basket inside dimensions | 610 x 430 x h280 mm n.b. height depends on selected lid type |

| Max load (parts) | 110 kg |

| Typical takt times | 10 – 15 min. n.b. actual time may vary due to process variables. |

| Wash and rinse storage tanks | 500 l each |

| Heating effect | 22.5 kW wash, 15 kW rinse, 11 kW drying |

| Ultrasonic effect | 3 kW, 25 kHz |

| Spray pumps | 350 l/min, 5 Bar |

| External dimensions | 2200 x 3350 x h2700 mm |

| Connected load | 70 kW |

| Voltage | 400/230 VAC 50 Hz |