Mineralogy Thin Section Preparation

The first step is sectioning. The aim of sectioning is to obtain a small piece of sample from big specimens. For big and irregular shaped specimens, Geocut is the perfect choice. For smaller specimens, you can use the Geoform..

The cut piece should be small enough to stick to a glass slide. Cutting petrographic samples are usually done with special diamond cutting discs. Cooling is done with fresh water. Cooling liquids are not recommended for most petrographic application, because chemicals in the cooling liquids may negatively effect the specimen for microscopic examination.

Preparing Glass Slide

Glass slides have to have a specific light transmittance and refractive index, Kemet provides high quality glass slides suitable for this. In order to stick a sample onto the glass slide, the surface of the glass slide has to be made rough by rubbing on SiC powder. Otherwise, the sample does not stick well on the glass slide and may slip during grinding. Add some water and silicon carbide powder on a metal plate and mix together. Rub one side of the glass slide on the SiC and water mixture and the same with the specimen.

Adhesive resins have to have specific light transmittance and refractive index otherwise, the microstructure can not be seen clearly under a polarised microscope. Epoxy can be used as adhesive resin (Kemet recommend KEPT Epoxy). The surface of the sample and glass slide have to be clean and dry before they can be joined well.

The Geofix is used for curing adhesive, with up to 12 specimens at the same time. The Geofix can also be put onto a hot plate in order to shorten curing time. Curing time without hot plate takes around 6-8 hours and curing time with hot plate takes around 2 hours.

Reducing Thickness of Mineral Samples (Sectioning)

Thickness of the specimen on the glass slide should be reduced by cutting in order to shorten grinding process. The cutting chamber of the Geoform can be used for this process. Place the glass slide on the vacuum chuck of the Geoform and turn on the vacuum and water. Cut the sample slowly by pushing the vacuum chuck towards the cutting disc. After cutting, the thickness of sample will be roughly 1.9 mm. Distance between the vacuum chuck and the cutting wheel can easily be adjusted as per required sample thickness.

The grinding chamber of the Geoform will be used for this process. The grinding operation is done using the diamond cup grinding wheel. Place the glass slide on the vacuum chuck and turn on the vacuum. Depending on the size of the glass slides you are using, up to 3 can be prepared at the same time. Move the vacuum chuck by using the micrometer until the glass slide touches the cup grinding stone. When the glass slide touches the grinding stone, set the micrometer to “zero”. Close the cover of the grinding chamber and the specimen is ready for grinding.

Turn on the water and press the start button. Grinding is done by pulling the grinding arm back and forth repeatedly. After grinding a couple of passes, you will feel that moving the arm becomes easier and that there is less grinding noise, this means that the material has been removed from the surface of the sample. You can now bring the specimen closer to the grinding stone by turning the micrometer. Grinding depth should not be increased more than 100 microns in one go as there would be a greater risk of the glass slide breaking. It is best to move the specimen closer to the grinding stone between 50 to 100 microns each time. When the thickness of the specimen reaches 200 microns, the grinding depth should be reduced to 20 microns. After that, continue with grinding a couple more passes. The cycle will continue until specimen thickness become 80 microns.

When you see thickness value around 80 microns on the micrometer, turn off the motor, water and vacuum. Take out the specimen.You will now see that there is a very thin layer of specimen left on the glass slide. Before the lapping operation, clean the specimen with water in order to wash away microparticules.

Lapping Mineral Samples

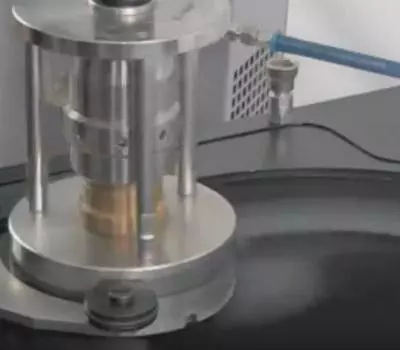

Final thickness of the specimen on the glass slide should be between 25 to 35 microns for microscopic examination. This thickness can be obtained using the KemTech III Thin Section Lapping machine with the vacuum jigs. Set the KemTech vacuum jig to the required final thickness and then mount the uniformly ground samples to the vacuum jig face. Lap on the KemTech III machine using a Silicone carbide/water mix until the jigs diamond faced stop ring fully contacts the cast iron lapping plate. There is a change in sound when this point is reached. This means the slides have been lapped to the set thickness.

Remove the slides from the jig and clean and inspect. The slides are now ready for polishing on the KemTech III. Clean the Vacuum jig in an ultrasonic cleaner to ensure all lapping slurry contamination has been removed and adjust the diamond stop ring so that it is above the vacuum face plate.

Polishing Mineral Samples

Using the KemTech III Thin Section Lapping machine, change the cast iron lapping plate to the aluminium lift off disc and mount a PSU-M polishing pad. Charge the Aku-Disp slurry pump (separate pump heads are available) with Diamond suspension and programme the pump to dispense a 2 second supply of slurry every 8-10 seconds. Mount the now lapped samples to the clean vacuum jig and polish on the PSU & MBL cloths working down the Diamond suspension micron size to the required thickness and surface finish, approx. 30micron. Remove the samples and clean. The slides are now ready for analysis.

Why Mineralogy is important

Mineralogy is the scientific study of minerals and their properties, including their crystal structure, chemical composition, physical properties, and geological occurrence. It is a crucial field of study for understanding the Earth's composition and the processes that have shaped it. Here are several reasons why mineralogy is important:

- Understanding the Earth's history: The study of minerals can provide insight into the geological processes that have shaped the Earth's history. For example, minerals that form only under specific conditions can help geologists reconstruct past environments, such as ancient oceans, volcanic eruptions, or meteorite impacts.

- Resource exploration: Minerals are essential resources for human society. They are used in everything from construction materials and electronics to medicine and energy production. Mineralogy plays a vital role in the exploration and extraction of these resources. By identifying the minerals present in a deposit and understanding their properties, geologists can determine the economic potential of a deposit and design the most effective methods for extraction.

- Environmental remediation: Minerals can also be used in environmental remediation, such as the treatment of contaminated soil and water. Mineralogists can identify minerals that have the ability to adsorb or chemically transform contaminants, and develop methods to use these minerals to clean up polluted sites.

- Planetary exploration: The study of minerals is not limited to Earth. Mineralogists also play a crucial role in the exploration of other planets, moons, and asteroids. By analysing the minerals present on these bodies, scientists can infer their geological history and assess their potential for supporting life or resources.

- Fundamental science: Mineralogy is a fundamental science that underlies many other fields of study, such as petrology, geochemistry, and materials science. By understanding the properties and behaviour of minerals at the atomic and molecular level, scientists can make advances in fields such as energy storage, catalysis, and nanotechnology.