What is Metallography? A Complete Guide to Metal Microstructure Analysis

Metallography is the scientific study and analysis of materials microstructure, particularly metals and alloys. Through systematic examination of a material's internal structure at microscopic levels, metallography provides critical insights into material composition, manufacturing processes, heat treatment effects, and mechanical properties. Analysis of a materials microstructure helps determine if the material has been processed correctly and is therefore a critical step for determining product reliability, quality control, failure analysis, and understanding why a material failed.

The field of metallography combines materials science, microscopy techniques, and analytical methods to reveal the internal architecture of metals. By preparing samples through careful sectioning, mounting, grinding, polishing, and etching, metallographers can examine grain structure, phase distribution, inclusions, defects, and other features that directly impact material performance and durability.

Understanding Microstructures in Metallography

Metallographic examination tells us a great deal about the identity, composition and thermomechanical history of a metal or alloy. An experienced metallographer will be able to glean information on all these aspects from observation of the microstructures at suitable magnification and using appropriate etching reagents.

Microstructural analysis provides crucial information about how a material was manufactured, whether it was cast or wrought, what heat treatments were applied, the presence of work hardening, and potential defects or discontinuities. These insights are invaluable for quality assurance, process optimisation, product development, and forensic failure investigations.

In examining a microstructure, it will be found convenient to classify the observations in terms of colour, grain size and shape, second phase shape, size and distribution (including porosity), and segregation effects. Each of these characteristics provides specific clues about the material's history and properties.

The basic steps for proper metallographic specimen preparation include:

- Sectioning and Cutting - Removing representative samples without altering microstructure

- Mounting - Encapsulating samples for easier handling and edge retention

- Grinding - Progressive removal of damaged surface layers

- Polishing - Creating a scratch-free, mirror-like surface

- Final Polishing - Achieving optimal surface finish for examination

- Etching - Chemical or electrolytic revelation of microstructure

- Microscopic Analysis - Optical or electron microscopy examination

- Hardness Testing - Mechanical property evaluation

Applications of Metallography in Industry

Metallographic analysis plays a vital role across numerous industries including aerospace, automotive, construction, oil and gas, power generation, electronics, and medical device manufacturing. Common applications include:

- Quality Control: Verifying that manufacturing processes produce materials with specified microstructures and properties

- Failure Analysis: Investigating component failures to determine root causes such as fatigue, corrosion, or improper heat treatment

- Process Development: Optimising manufacturing parameters like casting conditions, forging temperatures, or heat treatment cycles

- Material Selection: Comparing microstructures of different materials to select the most suitable for specific applications

- Research and Development: Studying new alloy compositions, processing techniques, and material behaviours

- Compliance Testing: Ensuring materials meet industry standards and specifications (ASTM, ISO, etc.)

Key Microstructural Features in Metallography

Colour Analysis

Colour - In the unetched state, this is a useful indicator for copper-base alloys. Pure copper is pinky red and undergoes a gradient in hue towards yellow as the zinc content of brasses increases to 40%. Phosphor bronzes display an opalescence or iridescence when etched. Colour variations can also indicate oxidation layers, different phases in multi-phase alloys, or specific compounds. Under polarised light, certain materials exhibit distinctive colours that aid in phase identification.

Grain Shape and Size

Grain Shape - Elongated columnar grains growing in from the side of the mould are indicative of a slowly cooled cast structure. Sometimes a layer of tiny chill crystals is seen at the surface. Grains with regular and uniform shape are termed polyhedral or equiaxed, and grain size may be referred to as coarse (>1mm and visible to the naked eye) or fine (10 µm - 1mm). Grain size gives an indication of the cooling rate of a cast metal, or annealing temperature for a cold-worked and recrystalised metal.

Some fcc metals such as α-brass exhibit annealing twins. These are bands of material across the grain in which the two parts are oriented symmetrically about an axis as mirror images of one another. In deformed metals, grains are elongated in the direction of working, and may exhibit strain bands on etching as direct evidence of deformation. The degree of grain elongation provides quantitative information about the amount of plastic deformation experienced by the material.

Grain size is a critical factor in determining mechanical properties. Fine-grained materials typically exhibit higher strength and toughness compared to coarse-grained materials, as described by the Hall-Petch relationship. Grain size is commonly measured using standardised methods such as the ASTM grain size number.

Segregation Effects

Segregation - Differential etching in the primary grains indicates coring or inhomogeneity of solute. Cast alloys with a wide melting range show coring, which often reveals a dendritic or fir-tree structure of the initially solidifying phase. The dendritic skeleton has branches or arms within which there may be interdendritic porosity or sponginess. Spherical coring may be present in some alloys.

Segregation occurs during solidification when solute elements partition between liquid and solid phases, leading to compositional gradients. This can significantly affect material properties, causing variations in corrosion resistance, hardness, and ductility within a single component. Homogenisation heat treatments can reduce segregation effects, though complete elimination is often difficult in cast structures.

Second Phase Structures

Second Phase - Usually appears as a duplex structure in which there is an intimate mixture of primary or secondary phases formed by a eutectic reaction, eutectoid reaction, separation from a saturated solid solution on continuous cooling, or by an isothermal ageing treatment. Eutectic structures exhibit a variety of morphologies including lamellar (or plate like), acicular (needle like) and rod-like formations.

In some systems the eutectic or eutectoid structure is given a special name, such as pearlite in steels (which appears in colonies), and Chinese script eutectic in Al-Si alloys. When growth of the primary phase is interrupted by a superseding eutectic or peritectic reaction, the growth morphology of the primary phase is exposed and preserved in the microstructure.

The appearance may range from a dendritic structure (either facetted or non-facetted), as in the phosphor bronzes in which globular forms are observed, to perfect cuboids as in the lead-antimony bearing alloys. Precipitation from the primary phase is often in the form of platelets along crystallographic directions, which in α-β brasses particularly is referred to as a Widmanstätten structure. The morphology, size, and distribution of second phases profoundly influence mechanical properties including strength, ductility, toughness, and fatigue resistance.

Inclusions in Metals

Inclusions - This term is generally reserved for a dispersed second phase which is not formed by a precipitation reaction. They are not taken into solution by hot working and align in stringers parallel to the working direction (eg. manganese sulphides in steels or Cu₂O in tough pitch copper), in extreme cases giving rise to laminations, as do slag inclusions in wrought iron.

Inclusions can be either indigenous (formed within the melt) or exogenous (introduced from external sources like refractory materials or slag). While some inclusions are intentionally added to improve machinability or other properties, excessive inclusions or unfavourable inclusion morphologies can act as stress concentrators and nucleation sites for cracks, significantly degrading mechanical performance, particularly fatigue life and impact toughness.

Metallography Machines Available from Kemet

Porosity and Voids

Porosity - Voids may appear in a cast microstructure. There may be a central cavity due to a primary or secondary pipe. Gas more often occurs as blow holes, pin holes or cavities (synonymous terms) which close up on working. Porosity can result from various causes including gas entrapment during solidification, shrinkage due to volumetric changes, or turbulent filling of moulds.

The type, size, and distribution of porosity significantly affect material properties. Large pores reduce load-bearing cross-sectional area and act as stress concentrators, while distributed microporosity can affect density, permeability, and overall structural integrity. Understanding porosity formation mechanisms is crucial for optimising casting processes and ensuring component reliability.

Special Metallographic Terms

Special Terms - These relate to graphite morphology in cast irons: flake, vermicular (worm-like) or nodular (spherical). Second phase material may also be described as fibrous (α in α-β brass) or rosette (Fae-rich phase in manganese bronze). In steels, terms like bainite, martensite, and austenite describe specific phases with distinct microstructural appearances and properties.

Understanding specialised metallographic terminology is essential for accurate communication among materials engineers, quality control personnel, and researchers. Standardised nomenclature, such as that provided by ASTM standards, ensures consistency in reporting and interpretation of metallographic observations across different laboratories and industries.

Advanced Metallographic Techniques

Modern metallography extends beyond traditional optical microscopy to include advanced analytical techniques:

Electron Microscopy

Scanning Electron Microscopy (SEM) provides high-resolution imaging and compositional analysis through Energy Dispersive X-ray Spectroscopy (EDS). Transmission Electron Microscopy (TEM) enables atomic-scale examination of crystal structures, defects, and precipitates, essential for understanding advanced materials and nanoscale phenomena.

Digital Image Analysis

Computer-aided image analysis allows quantitative measurement of microstructural features including grain size distribution, phase fraction, inclusion content, and porosity levels. Automated systems improve measurement accuracy, repeatability, and efficiency compared to manual methods.

Special Etching Techniques

Tint etching, heat tinting, and electrolytic etching methods reveal specific microstructural features that may not be visible with standard chemical etching. These techniques are particularly valuable for distinguishing between phases of similar appearance or for revealing subtle microstructural variations.

Cutting Equipment

Precision cutting and sectioning equipment for metallographic sample preparation without heat damage or deformation.

Grinding Systems

Professional grinding equipment and consumables for progressive surface preparation and material removal.

Mounting Presses

Hot and cold mounting systems for secure specimen encapsulation and edge retention during preparation.

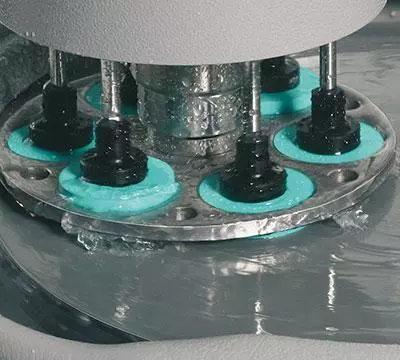

Polishing Equipment

Advanced polishing machines and consumables for achieving mirror-finish surfaces suitable for microscopic examination.

Metallography Standards and Best Practices

Metallographic practice follows established standards from organizations including ASTM International, ISO, and various industry-specific bodies. Key standards cover sample preparation procedures, etching protocols, grain size measurement methods, inclusion rating systems, and documentation requirements. Adherence to these standards ensures reproducibility, comparability of results, and regulatory compliance.

Best practices in metallography emphasize careful sample selection, proper preparation techniques to avoid artifacts, appropriate magnification selection, thorough documentation with representative photomicrographs, and accurate interpretation based on materials science principles. Continuous training and proficiency testing help maintain high-quality metallographic analysis.

The Future of Metallography

Emerging technologies continue to advance the field of metallography. Artificial intelligence and machine learning algorithms are being developed for automated microstructure recognition and classification. Three-dimensional characterization techniques including serial sectioning and X-ray tomography provide volumetric microstructural information. In-situ microscopy enables real-time observation of microstructural evolution during heating, deformation, or other processes, providing unprecedented insights into material behavior.

As materials become increasingly sophisticated—from advanced high-strength steels to additive manufactured components to novel alloy systems—metallography remains an indispensable tool for understanding, optimizing, and ensuring the quality of modern materials and components.