Struers Machine Comparison

The Forcipol 202 compared to the Struers Labosystem

The main advantages the Forcipol 202 has over the Struers Labopol-60 is that the automatic head (Laboforce-50/100) can only work on the single wheel, meaning that the other wheel can only be used for manual grinding/polishing. This is because the automatic head is not mounted in the centre of base unit. Compared to the Forcimat 52/102 automatic heads which can work on both of the wheels on the Forcipol 202.

The Struers Labopol-60 can work with Ø250 and Ø300 mm wheels but not with Ø200 mm wheels. Compared tp the Forcipol 102/202 which can work with Ø200, Ø250 and Ø300 mm wheels on the same machine.

Some other features the Struers Labopol-60 & Laboforce-50 do not have;

- There is no timer. Thus, it is not possible to set grinding/polishing time. Whereas the Forcipol 102/202 Control unit has time setting capability from 00:00 to 99:99 mins

- No audible signal

- It has only 4 pistons which means up to 4 specimens can be prepared in one cycle. Compared to the Forcimat 52 which has 6 pistons

- The pistons are spring loaded, compared to the Forcimat 52 which has pneumatic pistons

- It is not easy to adjust pressure for Laboforce-50 as it can only apply up to 30N force. Compared to the Forcimat 52 which can apply up to 60N force

- It has only 40 W motor power, Compared to the Forcimat 52 which has 100 W motor power

- It has fixed 150 RPM speed, no variable speed. Compared to the Forcimat 52 which has adjustable speed range from 50 to 150 RPM

- It is not possible to add peristaltic dosing units for more than 1 bottle. Compared to the Forcimat 52 which can be equipped with automatic peristaltic fluid dispenser for up to 7 bottles

*Free samples only available to UK. One sample per Company/Educational Establishment.

Aquapol - Diamond Suspension

Aquapol is the next generation of water based diamond suspensions for sample preparation. Available in monocrystalline (Aquapol-M) and polycrystalline (Aquapol-P). Aquapol is easy to clean and non-foaming.

- Manufactured to ISO 9001:2015 Quality Assurance standards

- Uniform suspension of diamond particles

- No agitation required

- Suitable for dispensing by Kemet Electronic Dispenser or alternative systems

- ZERO Volatile Organic Compounds (VOC*)

- Colour coded for easy identification

ZERO Volatile Organic Compounds (VOC) - not classified as an atmospheric pollutant and offer health and safety benefits. VOCs are organic chemicals that have a high vapour pressure at ordinary room temperature, some of which can be dangerous to human health and/or cause harm to the environment.

The Servocut 302 compared to the Struers Discotom 10/100

There are a number of features that the Servocut 302 has compared with the Struers Discotom 10/100. The main advantage the Servocut 302 has over the Struers Abrasimatic is the wheel speed can only be adjusted between 1500 to 3000 RPM. This RPM range may not be enough for some materials. The cut-off wheel speed of the Servocut 302-AA and 302-MA can be adjusted between 600 to 4000 RPM.

Some other features the Struers Discotom 10/100 does not have compared with the Servocut 302;

- No automatic chop cutting feature

- No manual X-axis movement feature

- No manual/automatic Y-axis clutch system

- No touch screen LCD screen

- No advanced fume condenser system is available

The Servocut 602 compared to the Struers Magnutom

SERVOCUT 602 can accommodate maximum Ø600 mm cut-off wheels, but the MAGNUTOM 5000 can only accommodate up to a maximum of Ø508 mm cut-off wheels. This means, SERVOCUT 602 has more cutting capacity and can cut larger specimens. In addition, Ø600 mm cut-off wheels are long lasting comparing with the Ø500 mm cut-off wheels. This means, operator does not have to replace cut-off wheels on the SERVOCUT 602 as often as MAGNUTOM 5000 which provides cost benefits. The MAGNUTOM 5000 XYZ and XYZR models have smaller clamping area than SERVOCUT 602-AX and 602-AX-R models. There is no competitor for the SERVOCUT 602-AX-R model, it's in a class of its own!

| Models | SERVOCUT | MAGNUTOM | |||

|---|---|---|---|---|---|

| 602-AX | 602-AX-R | 5000 YZ | 5000 XYZ | 5000 XYZR | |

| X-Axis | Yes | Yes | No | Yes | Yes |

| Y-Axis | Yes | Yes | No | Yes | Yes |

| Z-Axis | Yes | Yes | Yes | Yes | Yes |

| R-Axis (Rotary Table) | No | Yes | No | No | Yes |

| Max. Cut-off Wheel Diameter | Ø600 mm | Ø500 mm | |||

| Max. Cutting Capacity, Ø | Ø225 mm | Ø190 mm | |||

| Max. Cutting Capacity, # | 200hx550 mm | 184hx400 mm | |||

| Table Size, WxD | 772x710 mm | Ø710 mm | 751x781 mm | 524x781 mm | Ø533 mm |

| Multi-Target Cutting | Yes | Yes | Not Available | Not Available | Limited |

| Angle Cutting | Not Available | Yes | Not Available | Not Available | Yes |

| Segment, Diagonal and Combined Cutting | Optional | Optional | Not Available | Not Available | Not Available |

The Geoform compared to the Struers Discoplan-TS

There are a number of features that the Geoform has compared to the Struers Discoplan-TS. The main advantage the Geoform has over the Struers Discoplan-TS is that it has a small cutting chamber which allows a maximum disc size of Ø200 mm. Only specimens that have been glued on to the glass slides can be cut or small pieces can be cut by hand. It is not possible to mount a clamping device for large rocks.

Some other features the Struers Discoplan-TS does not have;

- No transparent cover for the cutting chamber. There is always risk of safety when machine is working

- No LCD touch screen available

- It has fixed disc speed at 1400 RPM. No variable disc speed is available

- It has no digital micrometer for grinding. Difficult to measure exact grinding depth

- It does not have an emergency stop button

- It has ceramic vacuum holder which could cause vacuum loss

- Poor illumination on the grinding compartment

Struers Discoplan-TS Grinding Cup Alternative with Kemet

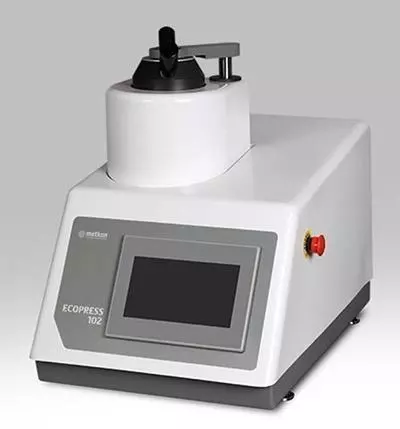

The Ecopress 102 compared to the Struers Citopress

There are a number of features that the Struers Citopress does not have compared with the Ecopress 102. The mould assemblies are assembled together with the heating & cooling unit. For this reason, the mould assemblies are very expensive (at least 2 times more expensive compared to the Ecopress mould assemblies) the mould assemblies for the Ecopress 52/102/202 are independent from the heating & cooling unit.

If there are any problems with the heating & cooling unit on the Struers Citopress, it has to be completely replaced with a new unit, compared to the Ecopress 52/102/202 which has 5 pieces of heating resistance. If one of them is broken, Ecopress can continue to operate fine with the remaining 4 resistances. In addition, the replacing resistances are very easy and cost effective.

- There are no pre-heating and pre-pressure features

- It is not possible to see pressure and temperature values in real time

The Micracut 152 compared to the Struers Minitom

There are a number of features that the Struers Minitom does not have compared with the Micracut 152. The Struers Minitom has no completely closed cutting chamber with magnetic safety switch which makes it a potential risk of safety. It can accommodate up to Ø127 mm cut-off discs compared to the Micracut 152 which can accommodate up to Ø150 mm discs.

It has a very low cutting capacity, up to Ø30 mm diameter compared to the Micracut 152 which has Ø50 mm cutting capacity. It has no optional Cutting Table Attachment which means it is not possible to cut PCB’s or extra flat specimens.

- Very low motor power, only 38 Watt compared to the Micracut 152 which has high torque 100 Watt brushless DC motor

- Very low cooling tank capacity, only 0.25 lt

- The gravity feed mechanism is between 0 to 350 grams compared to the Micracut 152 which has 0 to 1000 grams

- No digital display

- No digital micrometer

The Eloprep 102 compared to the Struers Lectropol 5

The Struers Lectropol 5 control unit for monitoring and programming is a little complicated compared to the Eloprep 102. It also requires a separate polishing and etching unit for low temperature (subzero) polishing. Some other features the Struers Lectropol 5 does not have;

- It does not have an emergency stop button

Samples are evaluated free-of-charge & reports are issued covering all aspects of the process & the likely consumable costs involved.

We provide a complete technical support programme as part of our package. Our team of technical experts are always on hand to offer advice and assistance.

With over 80 years of expertise, our experienced in-house technical support team can help you with your processes.