Surface Finishing Ceramic

Optimal surface finish outcomes for ceramic components can be achieved by utilising diamond abrasives in conjunction with composite plate technology. Kemet, a company with extensive experience in the realm of ceramic component finishing, has collaborated with leading manufacturers and OEMs to meet stringent specifications regarding flatness and surface finish quality.

Scope of Work: To Lap and Polish ceramic mechanical seals to Ra < 0.1 µm and flatness better than 1 light band

Equipment used:

Process

Parts were run on a Kemet Copper SP2 plate using Dycem as a fixture with a 8kg weight, process time of 10 minutes. Flatness Results: 0.0769 µm

Before Surface Finishing Ceramic

After Surface Finishing Ceramic

Flatness reading of ceramic mechanical seal

Scope of Work: To lap and polish 73 ceramic parts to Ra below 0.2 µm and flatness better than 0.0006mm in under 15 minutes

Equipment used:

- Kemet 36” lapping/polishing machine

- 36” diameter Copper SP2 Lapping plate

- Kemet Flatness gauge

- Kemox 0-400

- Kemet Liquid diamond 6 micron type K std

- Dycem faced pressure weight

- CO-42 cleaning fluid

- Profiled workholder

Process breakdown for ceramic parts

73 parts were placed in a profiled workholder, a Dycem backed 36” pressure weight was placed on top of components and they were run on a Kemet Copper SP2 plate for a total of 15 minutes. Parts were then removed and ultrasonically cleaned with Kemet type A cleaning fluid.

Surface Finish Achieved: 0.0971µm, Flatness Achieved: 0.00029mm

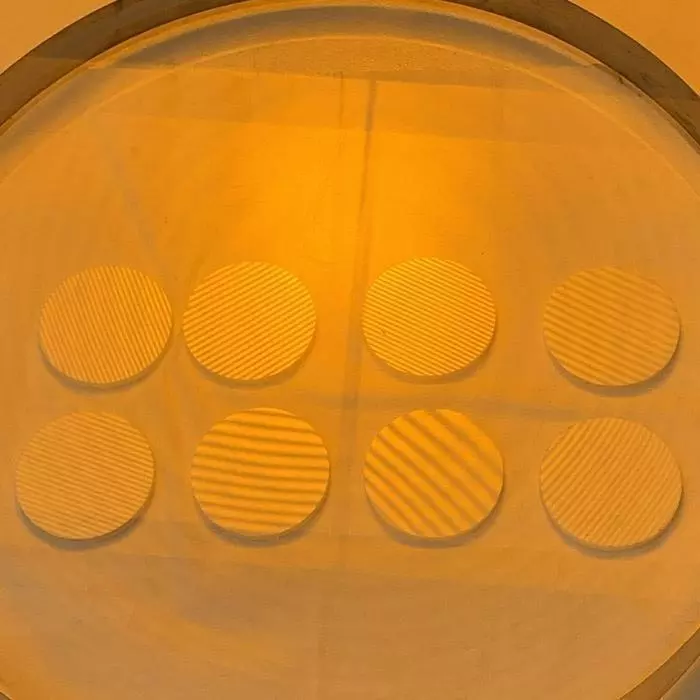

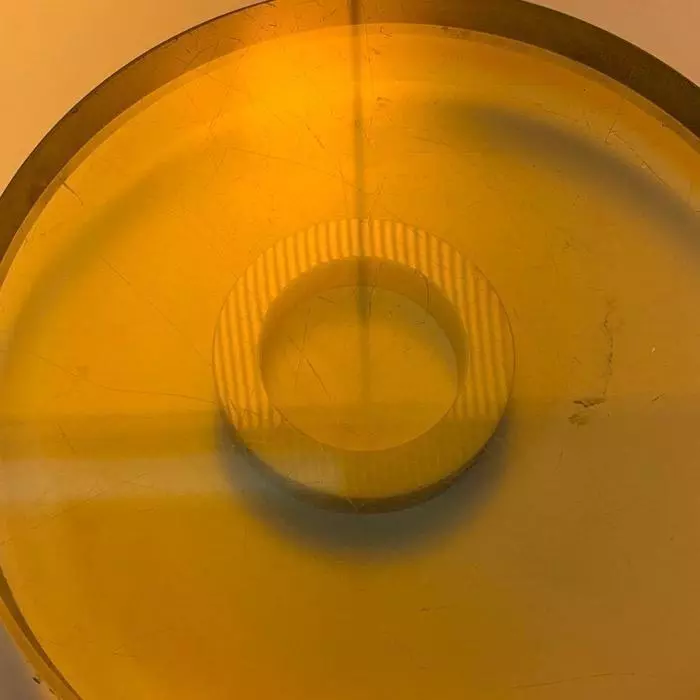

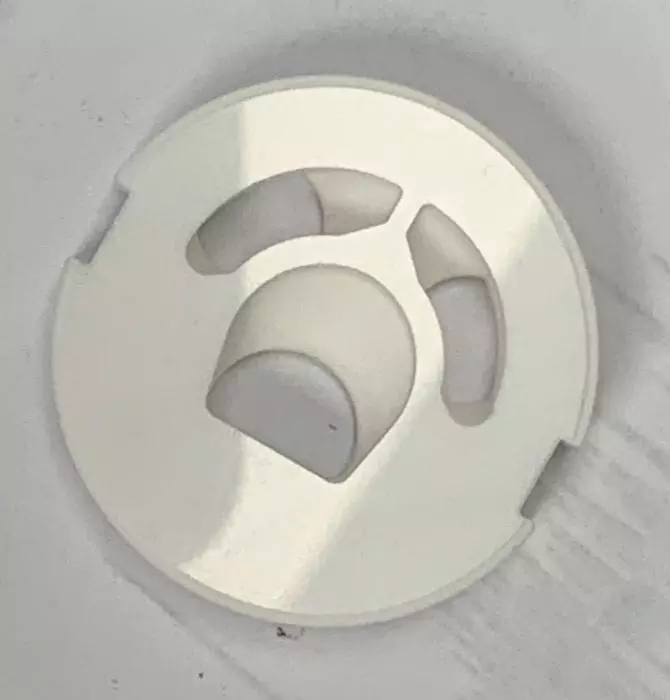

Profiled

workholder

Before Surface

Finishing Ceramic

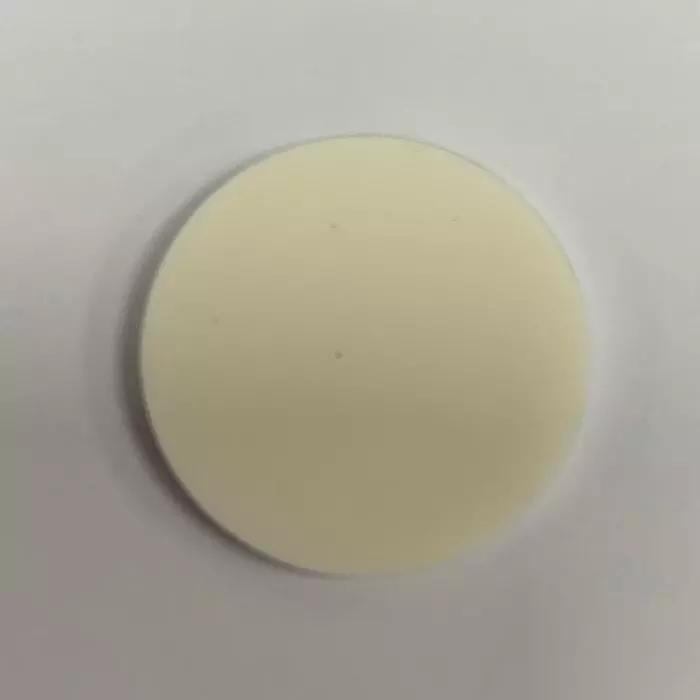

After Surface

Finishing Ceramic

Flatness Reading of Ceramic to better than 1 light band

Scope of Work: To lap 32mm diameter ceramic components scratch free and to an Ra better than 0.3 µm whilst achieving a stock removal rate of over 0.01mm in a 3 minute cycle. Flatness better than 0.6 µm

Equipment used:

- Kemet 15” lapping/polishing machine

- Cast Iron spiral grooved lapping plate

- Kemet Flatness gauge

- 3 KDS 1679 diamond slurry

- Ceramic control ring

- Dycem backed pressure weights (16kg)

- Type A ultrasonic cleaning fluid

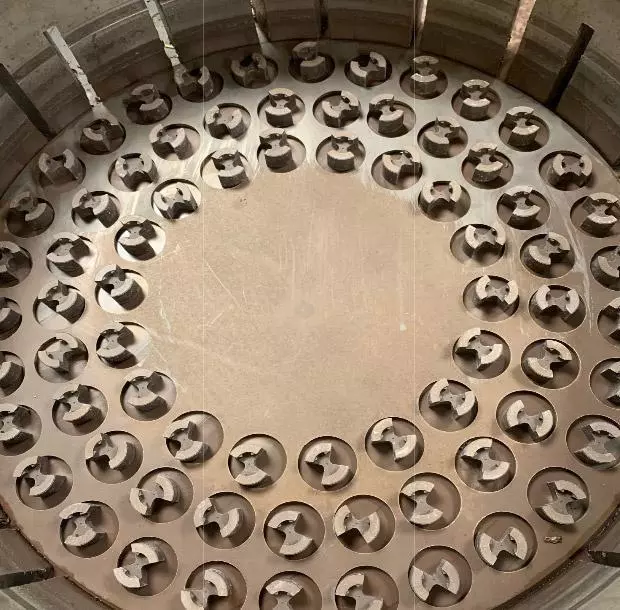

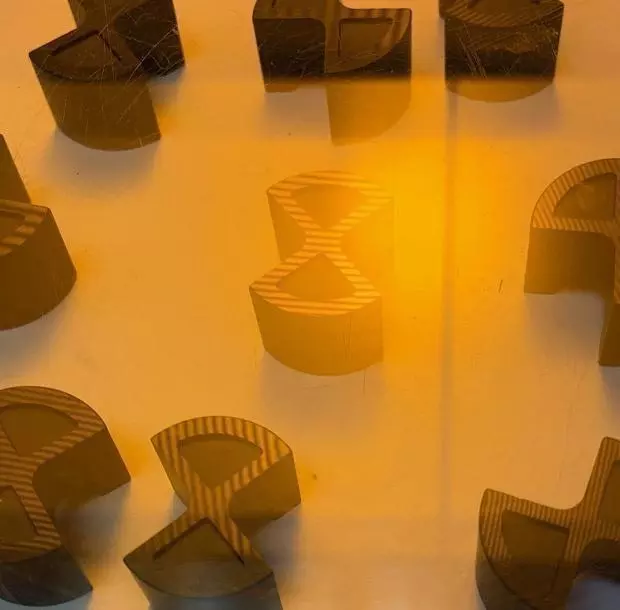

Process

5 off parts were placed equally into a ceramic control ring on a flat spiral grooved cast iron lapping plate. 4 dycem faced pressure weights were placed on top and the machine was run for 3 minutes with 3 KDS 1679 diamond slurry being dispensed at a ratio of 2 seconds of spray every 40 seconds. Parts were then ultrasonically cleaned with Kemet type A cleaning fluid. Ra achieved: 0.0814 µm, Flatness achieved: 0.3 µm (1 light band).

Before Surface Finishing Ceramic

After Surface Finishing Ceramic

Flatness reading of ceramic component

Scope of Work: To lap 4 x 30mm diameter ceramic parts to best surface finish possible (Target is Ra 0.025µm)

Stage 1 Equipment used:

- Kemet 15” lapping/polishing machine

- Kemet Iron plate, 15” diameter

- Kemet Flatness gauge

- Kemet Liquid diamond 14 micron type K

- CO-42 cleaning fluid

- Special handweight, 1.3kg with Kemtak plus

Stage 2 Equipment used:

- Kemet 15” lapping/polishing machine

- Kemet Copper SP2 plate, 15” diameter with spiral groove

- Kemet Flatness gauge

- Kemet 3 Micron Opti-pol liquid diamond

- CO-42 cleaning fluid

- Special handweight, 1.3kg with Kemtak plus

Process breakdown

A ceramic disc was placed in the centre of a special 1.3 kg handweight on a 15” Kemet Iron plate and run for 15 minutes at 40 RPM with Kemet liquid diamond 14 micron diamond slurry being dispensed at a ratio of 2 second of spray every 50 seconds. The parts were then sprayed of with CO42 cleaning fluid. The ceramic disc was placed in the centre of a special 1.3 kg handweight on a 15” Kemet Copper SP2 spirally grooved plate and run for 20 minutes at 40 RPM with Kemet 3 Micron Opti-pol diamond slurry being dispensed at a ratio of 2 second of spray every 50 seconds. The parts were then sprayed clean with CO42 cleaning fluid.

Flatness achieved: < 1 light band. Surface finish Achieved: 0.0092 µm

Before Surface Finishing Ceramic

After Surface Finishing Ceramic

Flatness reading of ceramic component