Surface Finishing Carbon Steel

Scope of Work: To lap and polish Carbon Steel (OD is 60 mm and ID is 18 mm) to better than Ra 0.05 µm with mirror finish, with no edge rounding

Stage 1 (Lap) Equipment used:

- Kemet 15” lapping/polishing machine

- Kemet Copper SP2

- Kemet Flatness gauge

- Kemet liquid diamond 6 micron type K std

Stage 2 (Polish) Equipment used:

Process breakdown for Lapping and Polishing Carbon Steel

Stage 1 lapping - 1 off part was placed centrally to a 15” pressure weight using Kemtak plus, the pressure weight was then placed into a control ring on a flat 15” Kemet Copper SP2 lapping plate and run for 15 minutes with Kemet liquid diamond 6 micron type K std being dispensed at a ratio of 2 seconds of spray every 45 seconds and cycled for a total of 15 minutes till cleaned up. The parts were then sprayed off with CO42 cleaning fluid.

Stage 2 polishing - The cleaned sample was then placed on a 15” ASFL polishing cloth in the middle of a plastic faced control ring and run for a time of 2 minutes with Kemet liquid diamond 3 micron type k slurry being dispensed at a ratio of 2 seconds of spray every 40 seconds. The sample was then cleaned with CO42 cleaning fluid and inspected for flatness. Ra achieved : 0.0079µm

Before Surface Finishing Carbon Steel

After Stage 1 of Surface Finishing Carbon Steel

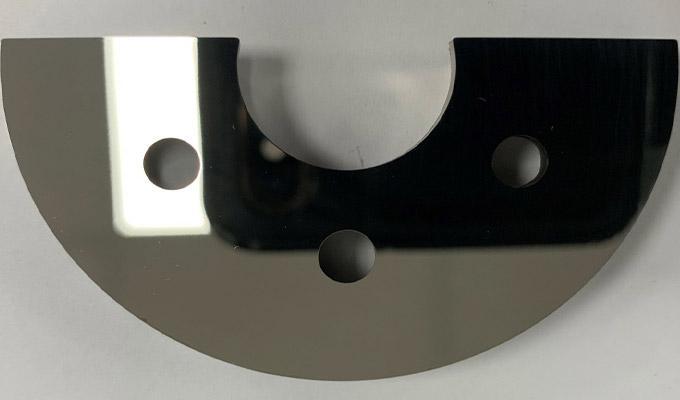

After Stage 2 of Surface Finishing Carbon Steel