Surface Finishing Aluminium

Lapping and polishing are crucial techniques for achieving a high-quality surface finish on aluminium. When aluminium parts are manufactured, they often have surface imperfections such as scratches, pits, or unevenness that can affect their appearance, performance, and durability. By using lapping and polishing techniques, these imperfections can be removed, creating a smooth and reflective surface that is free of defects. This not only enhances the visual appeal of the aluminium, but it also improves its corrosion resistance, wear resistance, and overall functionality. Additionally, lapping and polishing can help to create precise tolerances, which is essential for parts that require a tight fit or have strict dimensional requirements. Ultimately, the use of lapping and polishing for surface finishing aluminium is critical for achieving the desired aesthetic and functional properties, as well as ensuring the longevity and reliability of the finished product.

Scope of Work: To lap and polish various sizes of Aluminium light housings

Stage 1 (Lapping) Equipment used:

- Kemet 24” lapping machine

- Cast Iron lapping plate

- Kemet Flatness gauge

- Kemox 0-800s

Stage 2 (Polishing)

- Kemet 24” lapping/polishing machine

- ASFL polishing cloth

- 3 Micron type k diamond slurry

Process breakdown for polishing Aluminium light housings

Stage 1: All parts were spaced equally depending on quantity in a 24” control ring. A dycem backed 4kg pressure weight was place on top to act as a fixture. The machine was cycled on a flat cast Iron lapping plate with kemox 0-800s being applied by the abrasive pump for 5-10 minutes. They were then taken and cleaned off with Co42 cleaning fluid.

Stage 2: The cleaned up parts were then placed into a plastic faced control ring with a 4kg pressure weight placed on top. The machine cycled for 5 minutes on an ASFL polishing cloth with 3 micron type k diamond slurry being dispensed at a ratio of 2 seconds of spray ever 40 seconds. Parts were then cleaned with Co42 cleaning fluid.

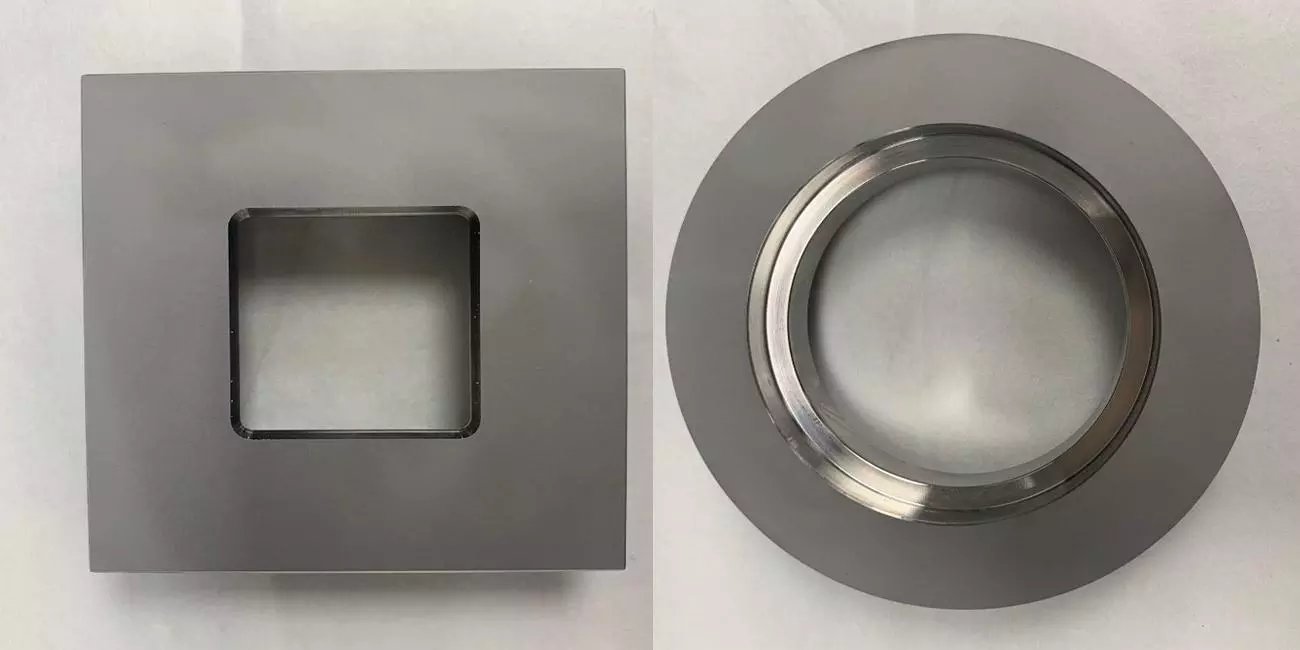

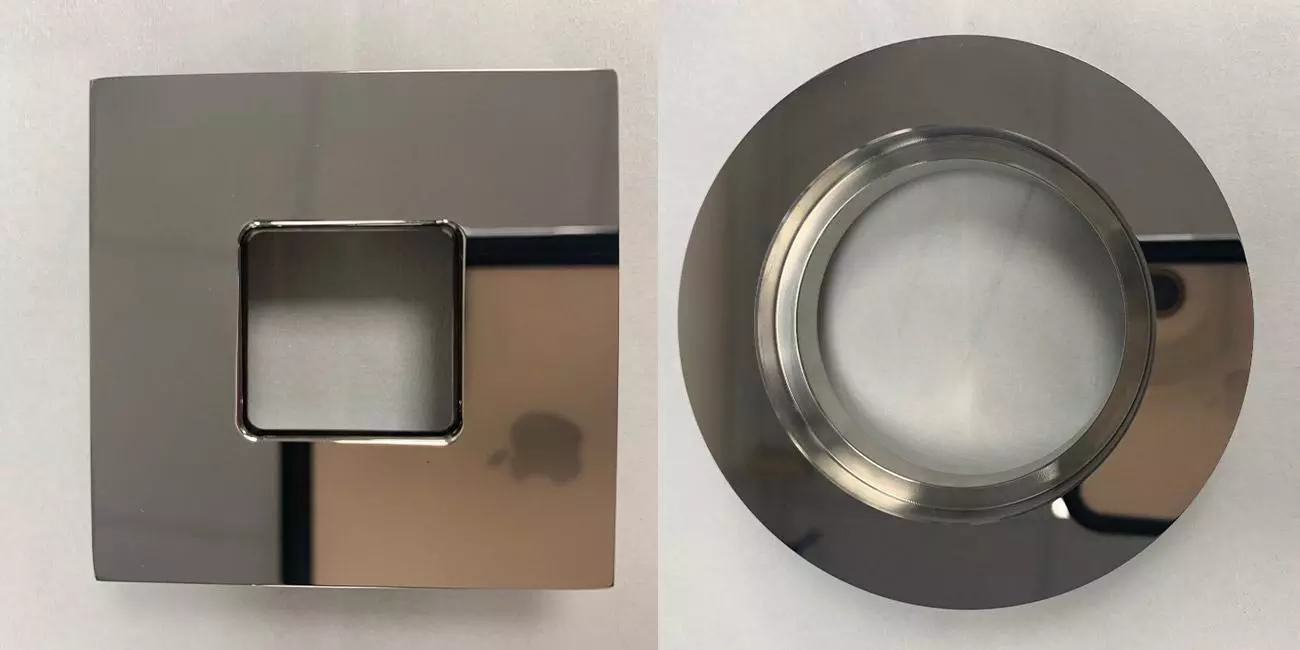

Before Surface Finishing Aluminium

After Surface Finishing Aluminium

Scope of Work: To produce best finish on ½” x 2” Aluminium strips leaving no abrasive particles in the samples

Stage 1

- Machine Type: Kemet 15 lapping/polishing machine

- Lap Plate: Cast Iron

- Abrasive Type/Grade: Kemox O-800S Aluminium oxide premixed slurry

Stage 2

- Machine Type: Kemet 15 COL-K Polishing machine

- Polishing pad: MRE short nap cloth

- Abrasive Type/Grade: Col-K (NC)

Process breakdown for Aluminium

We have selected a CMP process for the final polishing as this uses a chemical action to polish the surface of the components in place of a conventional abrasive type polishing process. This means that there should not be any abrasive left in the surface of the Aluminium. The polishing time was 80 minutes using the set-up that we had available for the parts, but with the addition of extra pressure this could be reduced.

Resulting Ra from this process: Ra 1.647µinch

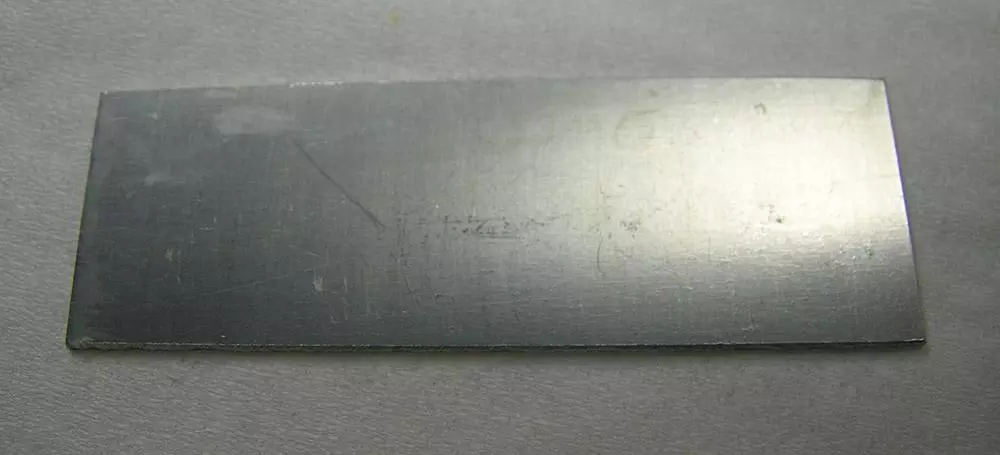

Before Processing Aluminium

After Processing Aluminium

Scope of Work: Polish to achieve a blemish free mirror finish on Aluminium

Component Details: Small Aluminium heat sink

Stage 1 (Grading stage)

- Machine Type: Kemet 15” 3 ring conventional lapping machine

- Lapping Plate: Cast Iron

- Abrasive Type/Grade: Kemox 0-800 Fine

A cast iron plate with Kemox 0-800 Fine Aluminium Oxide slurry was used to give the component a flat matt finish prior to polishing. The length of this stage depends upon the surface finish before lapping begins.

Stage 2 (Pre-polish)

- Machine Type: Kemet 15” 3 ring diamond lapping machine

- Lapping Plate: ASFL-AW silk cloth

- Abrasive Type/Grade: 3micron Type K STD diamond slurry

An ASFL-AW silk cloth with 3micron Type K STD diamond slurry was used to pre-polish, this produced a good reflective finish.

Stage 3 (Mirror Polish)

- Machine Type: Kemet 15” 3 ring diamond lapping machine

- Lapping Plate: Chem Cloth H

- Abrasive Type/Grade: Col-K

Finally a Chem Cloth H with COL-K was used to mirror polish. This produced a blemish free finish.