Lapping Polymer - Achieving Optimal Surface Finish

Lapping is a precision material removal process that involves the use of abrasive particles to achieve a fine surface finish and flatness on a variety of materials. This process is widely used in the manufacturing industry to produce high-quality components with tight tolerances. In this case study, we focus on lapping steel and polymer parts to the desired specifications using Kemet's lapping equipment.

The primary goal of this test was to lap four steel and four polymer parts to the desired specifications as per the drawing. The lapping process was carried out for ten minutes for all the six components. Non-slip fixtures were used to ensure that the components did not move during the lapping process. A 15" 4 Kg hand weight was used to apply the necessary pressure for the lapping process.

The lapping process was carried out using Kemet's 15" lapping/polishing machine. The machine is designed to provide a high level of precision and control during the lapping process. The Kemet Copper SP2 15" Lapping plate was used for the lapping process. The plate is made of high-quality copper, which provides excellent flatness and durability. The Kemet Flatness gauge was used to measure the flatness of the components during the lapping process. The abrasive used for the lapping process was Kemet Liquid diamond 6 micron Type K STD. The abrasive is designed to provide a consistent and uniform material removal rate. CO-42 cleaning fluid was used to clean the components after the lapping process.

The lapping process was carried out successfully, and the resulting surface finish was measured using the Ra (roughness average) parameter. The Ra for the steel parts was 0.0089 µm, and the Ra for the polymer parts was 0.0698 µm. The components were flat to 1-2 Lightbands, which is a measure of the flatness of a surface.

Equipment used for Lapping Polymer:

- Kemet 15” lapping/polishing machine

- Kemet Copper SP2 15” Lapping plate

- Kemet Flatness gauge

- Kemet Liquid diamond 6 micron Type K STD

- CO-42 cleaning fluid

Results data

The resulting Ra:

Steel 0.0089 µm

Polymer 0.0698 µm

All parts flat to 1- 2 Lightbands

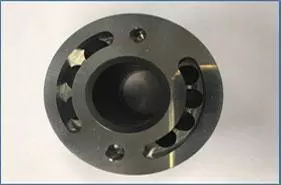

After Lapping Polymer