Lapping Hydraulic Pump - Case Studies

Scope of work: To lap flat hydraulic pump consisting of 2 flat surfaces

Hydraulic pumps are essential components of many industrial applications. They work by converting mechanical energy into hydraulic energy, which can then be used to power hydraulic machinery. One of the challenges with hydraulic pumps is maintaining their flatness. Over time, wear and tear can cause the flat surfaces of the pump to become uneven, leading to decreased efficiency and potential failures. Lapping flat hydraulic pumps is a critical process that requires precision and attention to detail. By using the proper equipment and following a well-defined process, the required flatness can be achieved, resulting in optimal function and performance of the hydraulic pump. .

Process Breakdown

- Separate the worn faces: Both worn faces of the pump are placed in separate control rings. This ensures that each face is lapped independently and that any unevenness is removed.

- Add weight to fixture the part: A dycem-faced hand weight is placed on top of the top plate to add weight and fixture the part. This helps to ensure that the pump remains in place during the lapping process and that it is evenly lapped.

- Run the body against the control ring: The body of the pump is run free against the control ring, ensuring that any high spots are removed.

- Cycle on the lapping plate: The pump is then cycled on the flat Kemet copper SP2 lapping plate. 6-micron type k is applied through a diamond dispenser at a ratio of 2 seconds of spray every 40 seconds. This ensures that the lapping compound is evenly distributed and that the surfaces of the pump are uniformly lapped.

- Clean up the surfaces: Both faces of the pump are cleaned up after 10 minutes using CO42 cleaning fluid. This ensures that all of the lapping compound is removed and that the surfaces are clean and free of debris.

- Inspect for flatness: Finally, the surfaces of the pump are inspected for flatness using the Kemet flatness gauge. This ensures that the pump meets the required flatness specifications and is ready for use.

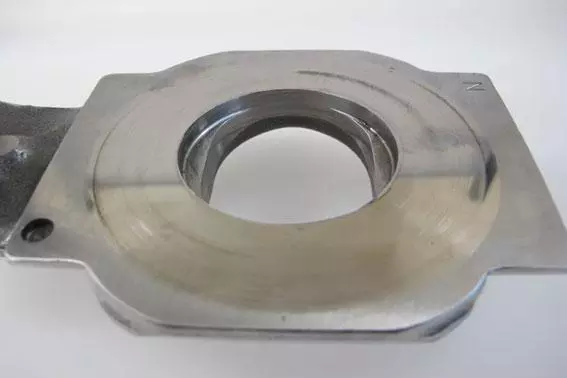

Before Lapping Hydraulic Pump Body

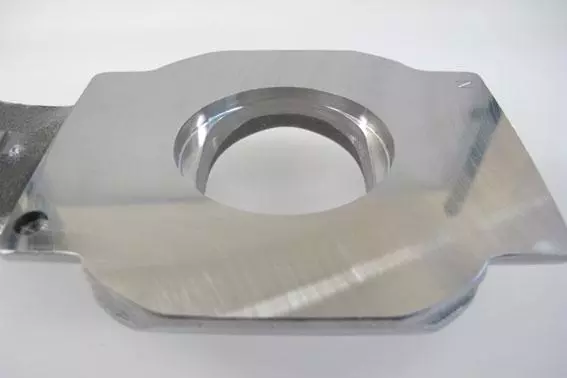

After Lapping Hydraulic Pump Body

Before Lapping Hydraulic Pump Top plate

After Lapping Hydraulic Pump Top plate

Test Requirements: Lap seal face

Component: Danfoss hydraulic pump

Machine Type: Kemet 15” diamond lapping/polishing machine

Lap Plate: Kemet Iron

Abrasive Type/Grade: 14 micron Type K Standard Diamond Slurries

| Process Breakdown | ||

|---|---|---|

| Stage | Plate/cloth type | Abrasive type/grade |

| Lapping | Kemet Iron | 14µ Type K Standard Concentration |

Process for Lapping Hydraulic Pump

Due to the shape of the part, the staging on the machine had to be removed. Once removed, the part was placed onto the plate allowing the bottom half of the part to hang off (See photo below). Once we had ensured the whole land area was seated on the plate, the part was held in place manually by hand whilst lapping. A suitable fixture will need to be made to automate the process. The part was cleaned with CO42 cleaning fluid then inspected; the drag finish on the part is a result of being in a fixed position and not being able to rotate. Due to the drag finish, we were unable to read an accurate result using the monochromatic light & optical flat. Surface finish (Ra value) after lapping: 0.0270 µm

Before Lapping Hydraulic Pump

After Lapping Hydraulic Pump

Positioning of Hydraulic Pump on lapping machine