Lapping and Polishing Silver (Coin Blanks) to improve Surface Finish

Silver is a widely used material in various industries, including electronics, jewelry, and aerospace, due to its excellent thermal and electrical conductivity. However, as with any material, silver requires proper surface finishing to meet the required functional and aesthetic requirements. Lapping is a commonly used surface finishing process that is particularly effective for silver due to its softness and malleability.

Surface finishing silver with the lapping process is vital as it produces a smooth and scratch-free finish, essential for aesthetic and functional purposes such as electrical conductivity. It also improves flatness, essential for precision-critical applications in electronic and aerospace component manufacturing, produces tighter tolerances, and improves durability, resulting in longer lifespan. Surface finishing silver with the lapping process is important for several reasons. It improves the surface finish of silver, making it scratch-free and uniform, necessary for aesthetic and functional purposes such as electrical conductivity. The process also enhances flatness, crucial for precision-critical applications such as manufacturing electronic components and aerospace parts. It can produce tighter tolerances, resulting in higher accuracy and precision, essential for precision bearings and valves. Lastly, the lapping process improves the durability of silver workpieces, reducing surface damage and wear, resulting in a longer lifespan.

Stage 1 (Diamond polish):

- Kemet 15” lapping/polishing machine

- ASFL polishing cloth

- Kemet Flatness gauge

- 3 micron type k std

- Custom profiled workholder

- Co42 cleaning fluid

Stage 2 (Polish) Equipment used:

- Kemet 15” lapping/polishing machine

- Chem H polishing cloth

- Plastic faced control ring

- Custom profiled workholder

- Col-K S

- deionised water

| Process Breakdown | ||

|---|---|---|

| Stage | Media | Plate/Cloth |

| 1 | 3 micron type k std | ASFL |

| 2 | Col-K S | Chem H |

Process for Lapping and Polishing Silver

The first stage of the process involved diamond polishing of the silver blanks. A custom profiled workholder was used to hold the blank in place. The workholder was then placed inside a 15” plastic faced control ring, which prevents the blank from moving during the process. An ASFL polishing cloth was used and the machine was run with 3-micron type K standard diamond abrasive and cycled for 5 minutes on the rough cut side and 3 minutes on the smooth side. The dispenser settings were 1 second of spray every 40 seconds. After each cycle, the blank was removed and cleaned with Co42 cleaning fluid to remove any residual abrasive particles.

The second stage of the process involved polishing the diamond-polished silver blanks to achieve a high surface finish. We used a Chem H polishing cloth and a plastic-faced control ring, similar to the first stage. The custom profiled workholder was used to hold the silver blank in place. Col-K S polishing slurry was used as the abrasive for the polishing stage. The machine was run for 5 minutes per side with Col-K S. After the polishing process, the blank was immediately sprayed with deionised water to remove any remaining polishing slurry. Finally, the blank was air-lined off to ensure no water droplets remained on the surface.

Lapping and polishing silver coin blanks are critical processes for achieving a high surface finish and flatness of metallic materials. By using specialised equipment and consumables, such as the Kemet 15” lapping/polishing machine, ASFL and Chem H polishing cloths, Col-K S polishing slurry, and the Kemet Flatness gauge, we were able to achieve the desired surface finish and flatness for the silver blanks.

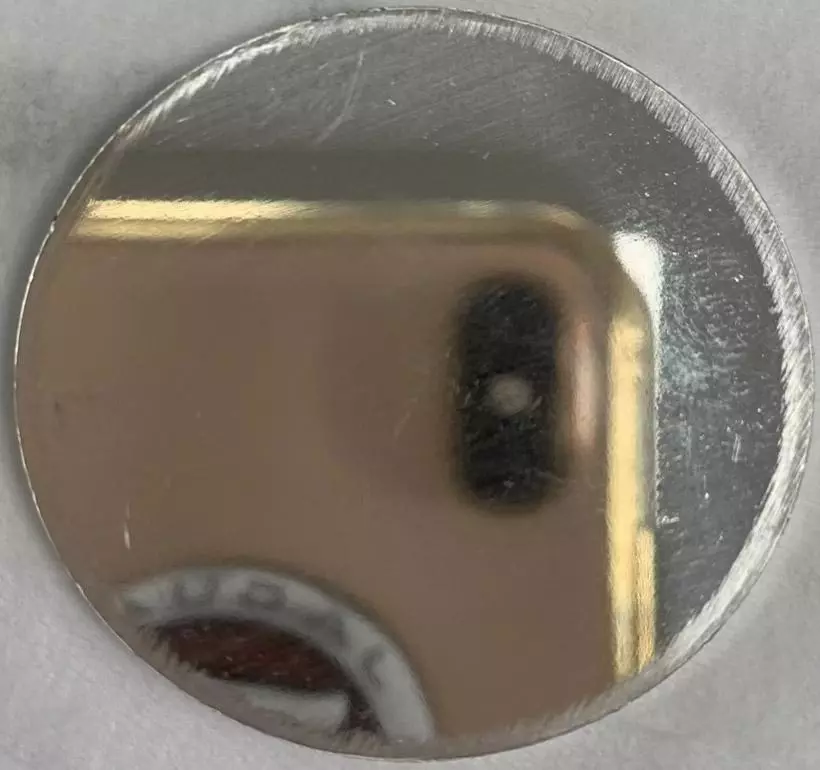

Pre-processed blank

Before Lapping Silver

After Polishing Silver