Lapping and Polishing Resin Squares

Stage 1 (Lap):

- Kemet 15” lapping machine

- Cast Iron lapping plate

- Kemet Flatness gauge

- Profiled work holder

- Kemox 0-800s

- CO-42 cleaning fluid

- 15” dycem faced pressure weight

Stage 2 (Polish) Equipment used:

- Kemet 15” lapping/polishing machine

- ASFL polishing cloth

- Profiled work holder

- 3 Micron type k diamond slurry

- CO-42 cleaning fluid

- 15” dycem faced pressure weight

| Process Breakdown | ||

|---|---|---|

| Stage | Media | Plate/Cloth |

| 1 | Kemox 0-800s | Cast Iron |

| 2 | 3 micron type k | ASFL |

Process for Lapping and Polishing Resin

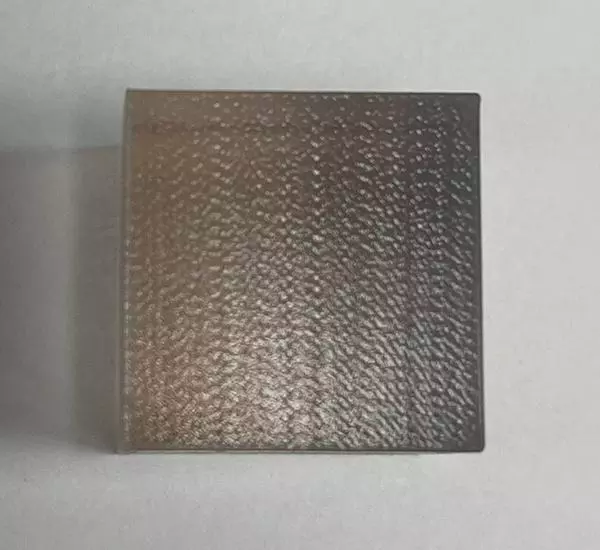

Stage 1: 10x resin squares were placed together and held in a profiled work holder and a dycem faced hand weight were placed on top. The parts were run on a flat cast Iron plate with kemox 0-800s being applied till the face had cleaned up. This stage was repeated on the other 5 sides of the resin, then cleaned with Co42 after the 6 cycles.

Stage 2: The 10x matt lapped resin squares were placed together and held in a profiled work holder and a dycem faced hand weight were placed on top. The parts were run on a ASFL polishing cloth with 3 micron type k being dispensed at a ratio of 2 seconds of spray every 45 seconds. The cycle time for each of the 6 sides were 10 minutes. Cleaned with Co42 after processing.

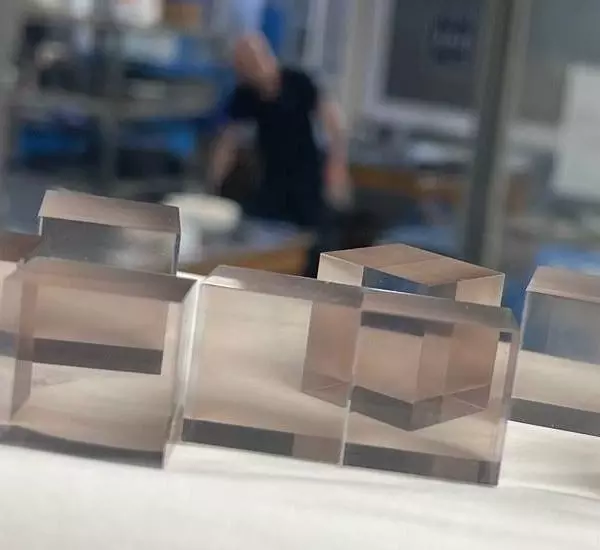

Before Processing

After Lapping

After Polishing