Factors to consider during the Lapping Process

Motion Type in the Lapping Process

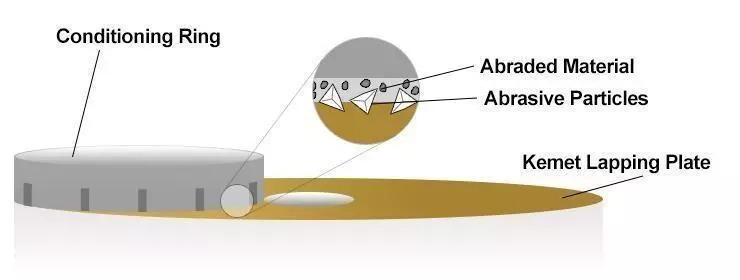

The perfect movement with single-sided lapping is that a workpiece slides over the lapping plate, the path of the relative movements at any point of the workpiece ought to be composed, forming a continual curving line, and the size of the path from each point should be the same. Motion type in the lapping machine is a crucial factor to ensure processing accuracy, the most common is the ring method, which places workpieces inside the rotating ring (or conditioning ring) set properly between the centre of the lapping plate. By changing the position of the reciprocal movement, and the number of rotations of the workpieces, this method allows a change in the density of the trajectories, and control over the amount of the lapping plate abrasion. They can also condition the shape (concave, convex or saddle) of the lapping plate.

Double-sided lapping, simultaneously laps both sides of the workpieces housed in the carriers (wafer holder) that are placed symmetrically on the lapping plate and held in between the upper and lower lapping plates, allowing the workpieces to have the same trajectories. As lapping pressure works better on thicker workpieces, it has the helpful effect of minimising the thickness variations and parallelism mistakes of the workpieces.

Lapping Surface Plate

One of the main factors in the lapping process is the lapping plate, its surface accuracy and material are critical. Lapping plates are made of different materials, depending on the workpiece being processed. Cast iron lapping plates consist of hard cementite and relatively soft ferrite, this is very beneficial to lapping as unevenness of the abrasive size (particle distribution of the abrasives) can be eased by the ferrite, whereas cementite can boost the cutting actions of the abrasives further. Composite lapping plates are typically made from a mixture of synthetic resins, metal particles and key bonding/hardening. The composite structure of the lapping plates allows for a combination of the strengths of each material, resulting in improved performance and durability compared to cast iron lapping plates.

The Lapping plate surface can be grooved, such as crosscut, concentric circle and spiral. These grooves are very effective not only in artificially creating functions similar to that of the cast iron plate, but also in holding and supplying lapping slurries and discharging cutting chips as well as in deconcentrating the pressure distributions.

Abrasives and Reagents in the Lapping Slurry

Alumina (Al2O3) or silicon carbide (SiC) are used for the lapping abrasives, as both are very hard with an efficient cutting action. Alumina abrasives are round-shaped with high toughness, which makes them hard to be crushed, whereas silicon carbide abrasives are easily crushed due to their sharp cutting edge.

Diamond slurries are often used in precision lapping applications, as they offer several advantages over traditional abrasives such as Alumina or silicon carbide. Diamond particles are harder and more durable than these traditional abrasives, allowing for faster material removal and improved surface finish. They also have a more consistent particle size and shape, leading to more predictable and repeatable results.

Diamond slurries are suspensions of diamond particles in a liquid medium, typically oil or water. The diamond particles in the slurry serve as an abrasive, removing material from the workpiece as it is rubbed against it.

Diamond slurries provide faster material removal, improved surface finish, and more consistent results compared to traditional abrasives.

The average size of the abrasives is proportional to the processing effectiveness and surface roughness of the workpiece. Typically, the size of the abrasives is sequentially reduced during the lapping process. This condition has been logical for ensuring excellent removal of the projected surface topographies and work-damaged layers created in the preceding processes so that the predetermined shape of the workpieces can be obtained.

Reagents in the lapping slurry work to lubricate and evenly disperse abrasives, allowing the rolling of the abrasives and discharge (transferring function) of cutting chips. Oil or oil-based water solutions are used when removal actions of the abrasives need to be subdued, and the coefficient of friction should be controlled.

Mechanical Lapping Conditions

Processing characteristics in lapping include removal rate, lapping friction, surface roughness, and processed-damaged layers, which are impacted by the material of the lapping plates, the abrasives and lubricating fluids, and the relative speed (rotation number, drive distance).

Typically, the following equation (Preston’s formula) is applied:

(Stock removal) = α x (processing pressure) x (relative speed) x (processing time)

The parameter α depends on the conditions such as size, type, and density of the abrasives.

Horizontal lapping friction whilst lapping is related to the mechanical properties of the workpiece. Typically, the harder the workpieces are, the friction tends to be higher, and when processing pressure increases, the processing friction also tends to increase. An increase of the processing friction and pressure occurs due to subsequent increment of the number of acting abrasives, and increasing cutting depth of the abrasives. However, when the processing pressure exceeds a certain level, processing friction becomes consistent as the removal action of the workpiece reaches the limit for crushing.