Advanced Materials and Surface Finishing Processes

What are Advanced Materials?

Any material that has an efficient performance either in terms of function or physical phenomenon as compared to conventional materials, is called an advanced material. These materials are designed using engineering technologies and specialised synthesis routes. These materials include biomaterials, nanomaterials, semiconductors, ceramics, high-value-added metals, composites, smart materials, etc. The different properties could be the high toughness, hardness, corrosion resistance, durability, shape memory, specific response when exposed to a specific environment or stimuli (smart materials), exceptional performance under heavy loads and much more.

What is Advanced Materials engineering?

To improve the designing and manufacturing process of devices for advanced applications, there is a need for improved properties in materials. It is also dependent on the availability of materials. Thus, the study of advanced properties, methods of manufacturing, and their engineering applications is known as advanced materials engineering. It is the most demanding field to improve the performance of existing devices that are based on smart materials, semiconductors, ceramics, composites, etc. The survival of materials under harsh circumstances and extreme environmental conditions is studied in this field. Moreover, the analysis of these materials during the service period and while in use is studied deeply. Not only the manufacturing and properties study is carried out but also the material failure analysis is performed in detail for future use. For the manufacturing processes of advanced materials, the study is closely related to mechanical engineering processes while the failure analysis and properties study is linked majorly with materials science and engineering. Thus, advanced materials engineering is a combination of other fields that are simultaneously used to develop advanced materials for improved performance.

Advanced Materials and Processes

If we create the materials on an atomic level or molecular level, this is called advanced material processing. These processing methods are intricately designed to develop materials having properties or characteristics for the chosen applications. These processes have been implemented to develop advanced materials for energy storage systems and devices, micro-device fabrication, electronics, sensors, medical equipment, industrial tools, etc. Different processes are being used to alter the material's microstructure and obtain a new set of properties. The selection of the manufacturing process depends on the type of advanced material that we are dealing with. For example, to manufacture the metallic base, we will need metal processing techniques such as cold welding, forging, additive manufacturing, soldering, crystal growing, etc. Metals are then mixed with polymers or ceramics to make composites through specialised processes. Chemical vapour deposition and physical vapour deposition are also used extensively to obtain highly pure materials with defined thickness and morphology. Surface properties are also very important in determining the interaction of the material with the environment. Therefore, surface finishing processes are used to add to the properties of advanced materials. There is a continuous improvement in the field of design and manufacturing processes of advanced materials to ensure high performance, low cost, longer life cycle, and related properties. Most demanding advanced materials include metal matrix composites (MMCs), polymer matrix composites (PMCs), ceramics matrix composites (CMCs), etc. In addition to these composites, there are many advanced materials for specialised applications.

Out of many advanced materials, some of them are described below concerning their manufacturing methods and surface finishing properties.

Silicon Carbide

Silicon carbide is abbreviated as SiC. It is one of the hardest known materials that is used for making cutting tools, sandpapers, and grinding wheels. SiC is an excellent thermal conductor that has oxidation resistance at very high temperatures. Due to these exceptional properties, it has found attention in the world of engineering. Lapping, grinding, abrasive grinding, and polishing are used normally for the surface finish of SiC.

Lapping and Polishing process for Silicon Carbide

Test Requirements: To lap a sample of resinoid silicon carbide to achieve a finish that can be measured optically to prove and determine the flatness.

Process for polishing Silicon Carbide

Stage 1 (Lap)

Equipment used: Kemet 15” lapping/polishing machine, Kemet copper lapping plate, Kemet Flatness gauge, 3 micron type k std diamond slurry, Dycem faced pressure weight, Co42 cleaning fluid

1 off sample of resinoid silicon carbide was placed in the centre of a control ring on a flat Kemet copper lapping plate, then a dycem faced hand weight was placed on top. The machine was then cycled with 3 micron type k being dispensed at a ratio of 2 seconds of diamond spray every 45 seconds till the disc had cleaned up which took 3 minutes. Taken off and cleaned with CO42 cleaning fluid.

Stage 2 (Polish)

Equipment used: Kemet 15” lapping/polishing machine, ASFL polishing cloth, Kemet Flatness gauge, Plastic faced control ring, 0.75-W2-PC-Std diamond slurry, Dycem faced pressure weight, Co42 cleaning fluid

The cleaned up sample was then placed inside a plastic faced control ring on a ASFL polishing cloth and a dycem faced hand weight was placed on top. The machine was then cycled for 10 minutes with 0.75 -W2-PC-STD being dispensed at a ratio of 2 seconds of spray every 45 seconds. Taken off and cleaned with CO42 cleaning fluid.

Flatness reading of silicon carbide sample

![]()

Resinoid silicon carbide sample before processing

![]()

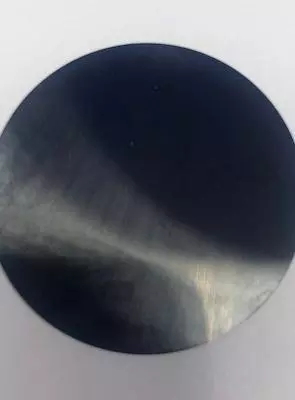

After processing silicon carbide

![]()

Fused Silica

Fused silica is the amorphous form of silicon dioxide that is used mainly in optical instruments like lenses, mirrors, metrology components, and parts of optoelectronic devices. As we know, there is a very high demand for the surface finish to aid the reflection, refraction, or transmittance of light. To fulfil this demand, abrasive powders have been used for surface finishing. Cerium oxide particles are used as abrasive powders. Moreover, Kemet has developed a polishing procedure that is very effective in obtaining a highly flat and pure fused silica surface.

Aluminum Silicate

As the name suggests, the compound is derived from alumina and silicon dioxide. It has a chemical formula of xAl₂O₃·ySiO₂·zH₂O. It has applications as a dyeing agent, filtering agent in pharmaceuticals, and raw material for the manufacturing of paper, cosmetics, and plastics. It is manufactured through precipitation on large scale followed by washing and drying. For materials manufactured with the addition of aluminium silicate, chemical mechanical processes are used for efficient surface finishing.

Silica Zircon

It is made by combining silica, alumina, and zirconia. This special blend is used for unidirectional solidification and single crystal growth. It has effective enamel and glazing properties. Its beads are used as grinding and polishing agents in the surface finishing techniques. Polishing methods are employed for the smoothness of silica zircon surfaces.

Lapping and Polishing process for Zircon

Test Requirements: To polish Zircon dials (ceramic), Ø36 x 0.4mm thickness to Ra of better than 0.0042 µm in under 45 minutes

Process for polishing Zircon

Stage 1. Lapping process

Equipment used: Kemet 15” Diamond Lapping machine, Kemet Iron lapping plate 15” diameter , Kemet liquid diamond 10 Micron Type K standard, Kemet flatness gauge, Dycem faced hand weight

Parts were waxed onto a 8kg handweight and placed in control ring and run for 10 minutes on Kemet Iron plate with 10 Micron liquid diamond for 15 minutes.

Stage 2. CMP Process

Equipment used: Kemet 15” Kemcol machine, MRE polishing cloth 15” diameter, Col-K (NC), Dycem faced hand weight, Plastic faced control ring

Parts were waxed into a 12kg hand weight and placed in control ring and run with Col-K (NC) and MRE pad for a total of 10 minutes.

| Results - Polished Zircon | |

|---|---|

| Ra | 0.0033 µm |

| Rt | 0.0252 µm |

| Rz | 0.0172 µm |

| Process Time | 25 Minutes |

Before polishing Zircon

After Kemet Iron stage

After CMP stage

Alumina

Alumina is a form of aluminium oxide (Al2O3) having a porous and granular structure. It is prepared at neutral pH and used mostly in the dry-activated form. It is mostly used in spark plugs, cutting tools, abrasion-resistant tools, tap washers, and monolithic refractories. Alumina is extracted from bauxite using two-step processes namely the digestion process that uses caustic soda for the separation of aluminium hydroxide and followed by calcination to remove water. To make parts from alumina powder, different manufacturing processes are used. It includes moulding, powder processing technology, and sintering techniques. After making the parts, different surface finishing operations are carried out. Kemet offers excellent surface finishing processes for alumina, most commonly used are polishing and grinding. A lapping process is also used before polishing for surface smoothness.

Aluminium Nitride

Aluminium nitride with a formula of AlN is famous for its very high thermal conductivity while being a good electrical insulator. AlN finds its applications in microwave devices, electronic packages, optoelectronics, heat spreaders, and electrical insulation for microdevices and lasers. It has a very good heat sinking property that makes its use excessive in the heat removal processes. Additive manufacturing processes are used for making these parts with a need for a surface finishing process that includes a highly precise lapping process and polishing technique. A highly precise lapping process can be obtained using Kemet lapping machines which can achieve up to 0.003 mm flatness results. With these methods, a very precise surface finish can be achieved.

Zirconia

Zirconia is the crystalline form of zirconium oxide. It exists in monoclinic crystal systems and is widely used in dental applications such as making dental crowns due to its excellent corrosion-resistant properties and high strength as compared to metals. The surface of zirconia parts can be treated by polishing, Kemet can be used to ensure the correct surface roughness value being obtained by the processes, inline with Surface finishing standards.

Lapping and Polishing process for Zirconia

Test Requirements: To lap Ceramic Air Flow Disc to Drg. Ra 0.5-1µinch, Flatness 1-5µinch.

Component/Material: 10 x Zirconia Ceramic discs

Process for polishing Zirconia Ceramic

Machine Type: Kemet 15” diamond lapping/polishing machine

Lap Plate: Kemet Copper

Abrasive Type/Grade: Kemet Diamond Slurry Type K 6 micron Standard

Additional Pressure: 2 x 4 Kg hand weights for Zirconia parts.

| Process Breakdown | |||

|---|---|---|---|

| Component | Plate/cloth type | Abrasive type/grade | Process time |

| Zirconia | Kemet Copper | Type K Standard Diamond slurry | 12 minutes |

Comments: Parts were processed using a Kemet Copper plate and Kemet Liquid diamond Type K 6 Micron standard. We have produced a process to suit both parts with no need to change the machine set-up when changing from 1 part to another.

Results: Parts were lapped to generate the surface finish Ra target values. The recommended process successfully meets the Ra requirements. The flatness results show the Kemet process has improved the flatness of the Zirconia pieces.

| Component | Flatness before | Flatness after | Ra produced by Kemet |

|---|---|---|---|

| Zirconia | 52µinch | 11.6µinch | 0.275µinch |

Air Flow Disc before polishing

Air Flow Disc after polishing

Flow Volume Disc after polishing

Brazing Materials

Solder and filler materials are used as brazing materials. These are fusible metal alloys that are used to join metal parts permanently. Brazing materials include alloys of tin, zirconium, lead, silver and indium. Acid core and rosin core are used for brazing metals. There is a need for the right surface finishing technique to save the brazed materials from oxidation. One of the commonly used processes is hot air surface leveling. Kemet also offers high-quality surface finishing processes for brazing materials such as dry electropolishing and centrifugal polishing. These processes remove micro-scratching and do not disturb the tolerances of given materials.

CVD Silicon Carbide

CVD SiC is used for the fabrication of fine and intricate parts. It also generates tiny holes with high precision. It also offers a very high thermal conductivity of 150 W/mK. CVD SiC is usually used for semiconductor processing applications, erosion resistance, and thermal shock resistance. Chemical etching is mostly used for surface finishing of CVD SiC. Liquid electropolishing can also be used for this purpose as it reduces the surface roughness to about 50%.

These materials have obtained much attraction in the modern world due to their advanced properties and prospective uses in future applications. For handling of these materials, we need effective manufacturing processes as well as excellent surface finishing methods to enhance their efficiency and improve their working. It will add to the quality of processes in which these materials are being used.