Ultrasonic Cleaning Screws / Bolts / Studs - Case Study

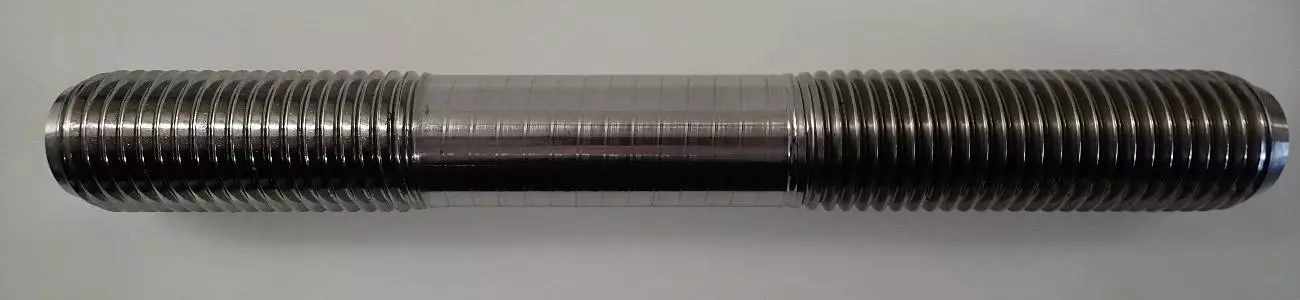

Component: Studs

Material: Steel

Contamination prior to cleaning: Oil, small machine particles

| Ultrasonic Cleaner | Cleaning Agent | Temperature(s) | Concentration |

|---|---|---|---|

| Versa 120 Genius+ | Decospray TM | 70°C | 3% |

| Versa 120 Genius+ air bubble agitation & auto-pruge | Tap water | Ambient | 100% |

| Versa 120 Genius+ | DI water | 40°C | N/A |

| Versa 120 Genius+ Hot air dryer | N/A | 70°C | N/A |

Note: All stages were allowed to reach the required temperature and degas before cleaning.

Process for cleaning Studs:

Stage 1: Decospray TM - DECOSPRAY TM is a slightly alkaline liquid used for ultrasonic or spray cleaning of metals. It’s a non–foaming product compatible with sensitive metals and is designed to rapidly and efficiently separate mineral oils for perfect degreasing. A gravity oil separation system was used for these trials. The Versa Genius+ 120 was filled with tap water then diluted with a 3% concentration of Decospray TM. As the removed oil contamination will float on the surface of the water, a closed-loop compact storage tank with a pump, coarse particle filter and gravity-based oil separation system was used.

Stage 2: Tap water rinse - Next, the parts were rinsed in tap water with the auto-purge feature and air bubble agitation. The auto-purge feature adds freshwater automatically in conjunction with the treatment cycle by opening a solenoid valve. Excess water is led to drain through overflow weir. This ensures all detergent carry-over is removed. Excess detergent carry-over can result in stains. The air bubble agitation feature increases the efficiency of immersion rinsing, The treatment timer controls air bubble agitation via a solenoid valve.

Stage 3: DI water rinse - To ensure a spot-free finish the parts were rinsed in DI water for 1 minute with 40Khz ultrasonic cavitation. Rinsing in tap water alone can leave mineral marks and cause stain/rust.

Stage 4: Hot air dry - Lastly, the parts were all dried in a hot air dryer at 70°C for 10 minutes

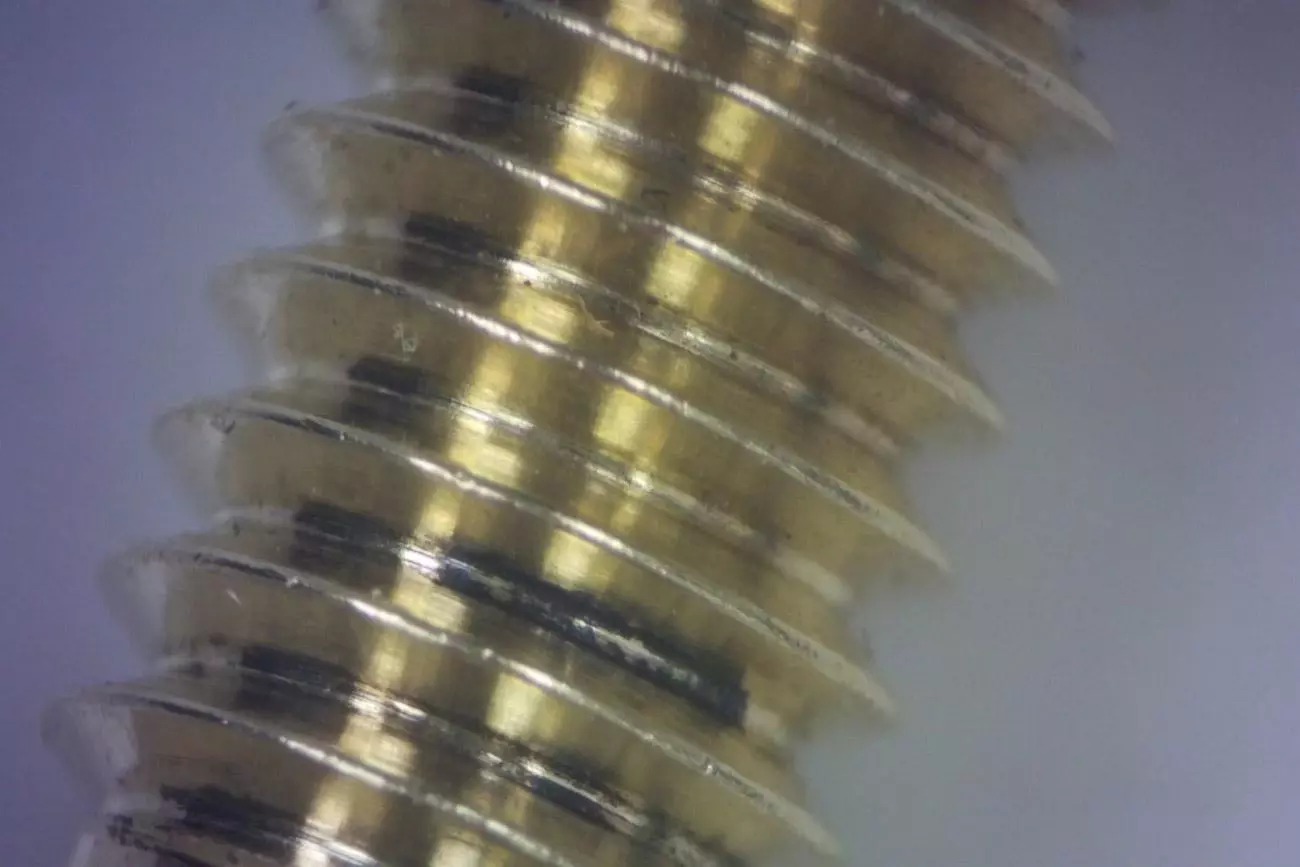

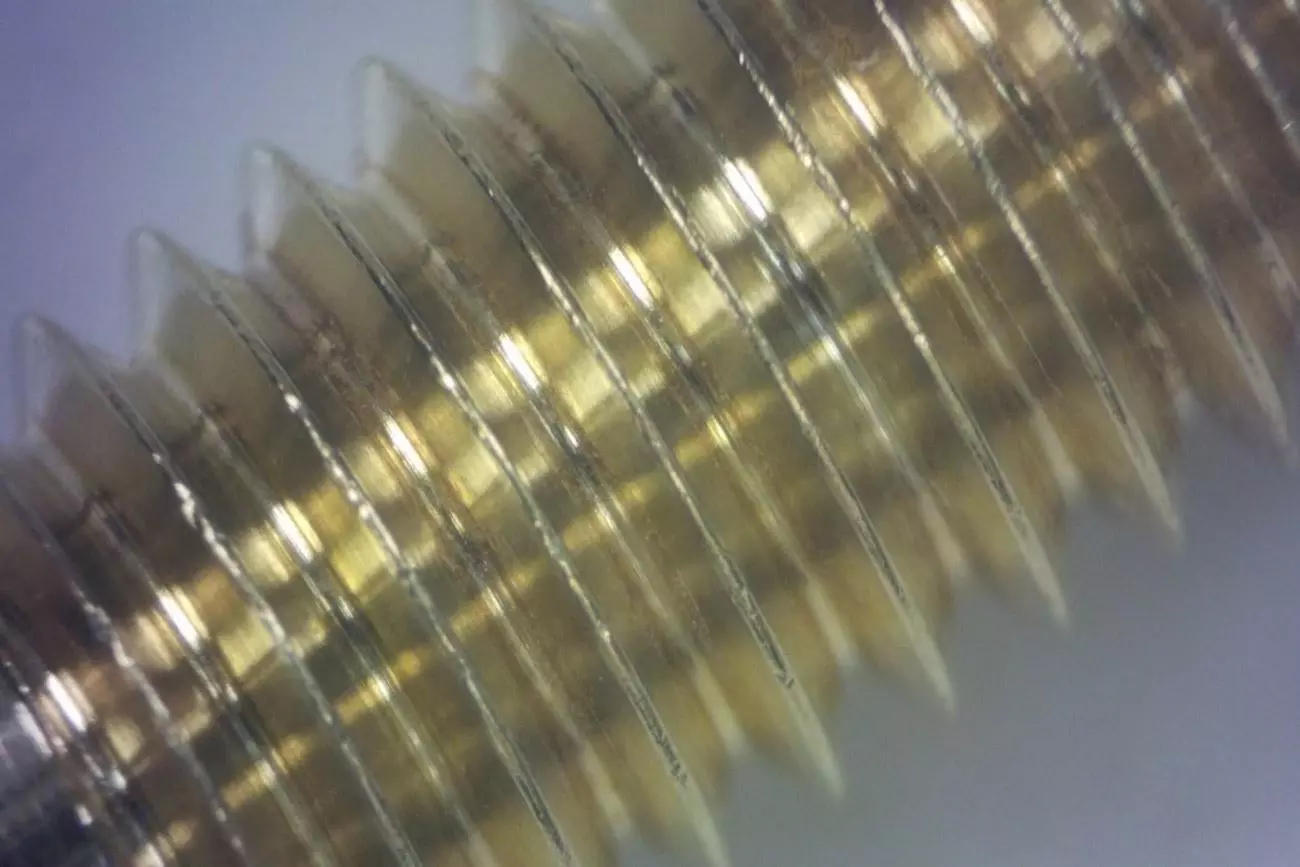

Component: Screws / Bolts

Material: C2121 Brass

Contamination prior to cleaning: Machine debris, light surface commination, oil

| Ultrasonic Cleaner | Cleaning Agent | Temperature(s) | Concentration |

|---|---|---|---|

| Versa 120 Genius+ | Galvex 20.02 | 60°C | 3% |

| Versa 120 Genius+ air bubble rinse | Tap water | 22°C | 100% |

| Versa 120 Genius+ Hot air dryer | N/A | 70°C | N/A |

Note: All stages were allowed to reach the required temperature and degas before cleaning.

Process for cleaning Machined Bolts / Screws:

Stage 1- Galvex 20.02

Galvex 20.02 is a light alkaline liquid, used for the removal of polishing compounds in ultrasonic or soaking processes. It is compatible with all metals except carbides and can be easily rinsed leaving a bright & spot-free finish. It offers complete removal of polishing compounds, light oils, grinding oils and fingerprints and is highly efficient on brushed, satin and stippled parts (complex geometry). The tank was initially filled with tap water, then diluted with a 3% concentration of Galvex 20.02 and allowed to reach the required temperature of 60°C. Initially cleaned for a cycle time of 10 minutes using the basket dunking.

Stage 2 – Tap water rinse

The parts were then rinsed for 2 minutes in tap water using the air bubble agitation feature. The air bubble agitation increases the efficiency of immersion rinsing. The treatment timer controls air bubble agitation via a solenoid valve. The auto purge feature was also used to wash away Galvex 20.02 detergent carry over. The auto purge feature adds fresh water automatically in conjunction with treatment cycle by opening a solenoid valve. Excess water is led to drain through the overflow weir, without this feature, the tank would quickly become polluted and would need to be drained, cleaned and refilled to ensure rinse water quality is kept high.

Stage 3 – Hot air dryer

The parts were then dried for 10 minutes at 60°C in the hot air dryer. Upon inspection, the results looked good, the internal threads were free from debris and oil and appeared much brighter.

Before cleaning Screws / Bolts

Click on images below to view larger version