Ultrasonic Cleaning Surgical Instruments & Medical Devices - Case Study

When it comes to cleaning medical devices and instruments, the stakes are high. Ensuring that these items are properly cleaned and sterilised is crucial to preventing the spread of infection and disease. One method that has proven effective for cleaning medical devices and instruments is ultrasonic cleaning. Ultrasonic cleaning uses high-frequency sound waves to create tiny bubbles in a liquid cleaning solution. These bubbles then collapse, creating a scrubbing action that effectively removes dirt, grime, and other contaminants from the surface of the items being cleaned. This method is particularly effective for cleaning items with complex shapes and crevices, such as medical instruments.

To illustrate the effectiveness of ultrasonic cleaning for medical devices and instruments, let's look at a case study involving these medical device materials; stainless steel, chrome plated brass, silicone, and rubber. The items in question had been contaminated with miscellaneous fibres, unidentified dirt and powders, loose metal burrs, metal shavings, oil residue, and marker pen markings.

The first step in the cleaning process involved disassembling the items to ensure that all surfaces could be properly cleaned. The items were then placed in an ultrasonic cleaning tank filled with a cleaning solution specifically formulated for medical devices and instruments. The ultrasonic cleaning process was carried out for a total of 10 minutes, with the frequency and temperature carefully controlled to ensure optimal cleaning. After the cleaning cycle was complete, the items were rinsed thoroughly in tap water and and second rinse with Deionised water to remove any remaining cleaning solution.

The results of the ultrasonic cleaning process were impressive. All of the items were thoroughly cleaned, with no visible signs of contamination or residue. The complex shapes and crevices of the items were also effectively cleaned, thanks to the scrubbing action of the ultrasonic waves. In addition to its effectiveness, ultrasonic cleaning is also a relatively quick and easy process, making it an ideal choice for busy medical facilities. And because it uses a liquid cleaning solution rather than harsh chemicals, it is a safer and more environmentally friendly cleaning method.

Material: Stainless steel, Chrome plated brass, silicone & rubber

Contamination prior to cleaning: Miscellaneous contamination fibres, unidentified dirt and powders, loose metal burrs, metal shavings, oil residue and marker pen markings

| Ultrasonic Cleaner | Cleaning Agent | Temperature(s) | Concentration |

|---|---|---|---|

| Versa 120 Genius+ | Rodaclean 2018 | 60°C | 5% |

| Versa 120 Genius+ | Tap water | 22°C | 100% |

| Versa 120 Genius+ | Galvex 20.01 | 60°C | 3% |

| Versa 120 Genius+ | Deionised water | 22°C | 100% |

| Versa 120 Genius+ Hot air dryer | N/A | 110°C | N/A |

These Cleaning fluids are compatible with validation standards

- Cleaning:

- ISO 19227 - 2018 (UE)

- ASTM 3127 - 2016 (USA)

- Characterization of inorganics:

- ISO 10993 - 18

- Passivation:

- ASTM A967M - 17

Note: All stages were allowed to reach the required temperature and degas before cleaning.

Process for cleaning Medical Devices:

Stage 1- Rodaclean 2018: Rodaclean 2018 was used for the initial wash. With its high sodium and potassium hydroxides concentration, it removes soluble oils, polishing pastes, as well as all types of abrasives. The parts were then placed inside the wash basket and cleaned for a total cycle time of 10 minutes. Basket dunking was used throughout the cycle to ensure optimal results.

Stage 2 – Tap water rinse: The parts were then rinsed in tap water for 2 minutes to remove any remaining debris and detergent residue. We used the air bubble agitation feature to increases the efficiency of immersion rinsing. Treatment timer controls the air bubble agitation via a solenoid valve which is fully controllable, giving a 'Jacuzzi' like effect. We used the auto-purge feature, this adds fresh tap water automatically in conjunction with the treatment timer cycle by opening a solenoid valve. Excess water is led to the drain through the overflow weir. The flow is fully adjustable with a gate valve. The aim here is to remove the detergent carry over and keep water quality high.

Stage 3 – Galvex 20.01: The parts were then cleaned in a second detergent tank using Galvex 20.01. Galvex 20.01 is a universal detergent without amines, allows degreasing on all materials and offers a high degree of finish due to its excellent rinsability. Very versatile, for interoperation cleaning (removal of polishing pastes), surface preparation before passivation, anodizing, electrochemical polishing or final cleaning before sterilization. The parts had a 5-minute cleaning cycle with the basket dunking feature used throughout for optimal results.

Stage 4 – Tap water rinse: The parts were then taken back to stage 2 tap water rinsed and rinsed as before to remove all detergent residue. 2-minute rinse cycle with air bubble agitation and auto-purge.

Stage 5 – DI water: The parts were then rinsed in deionised water for 2 minutes with 40Khz ultrasonic cavitation along with basket dunking.

Stage 6 – Hot air dry: Lastly, the parts were dried in the hot air dryer at 110°C for 10 minutes. Some parts held pooling water due to their shape, so the temperature must be above 100 to boil away any sitting water.

Note: All parts except the blue plastic components, followed the above process. The blue plastic parts were washed in Galvex 20.01 followed by a tap water rinse then a DI rinse, and lastly, hot air dried. The Rodaclean 2018 had started to remove the black anodising from the scissors. Rodaclean 2018 is too strong, these parts should be washed in Galvex 20.01 only.

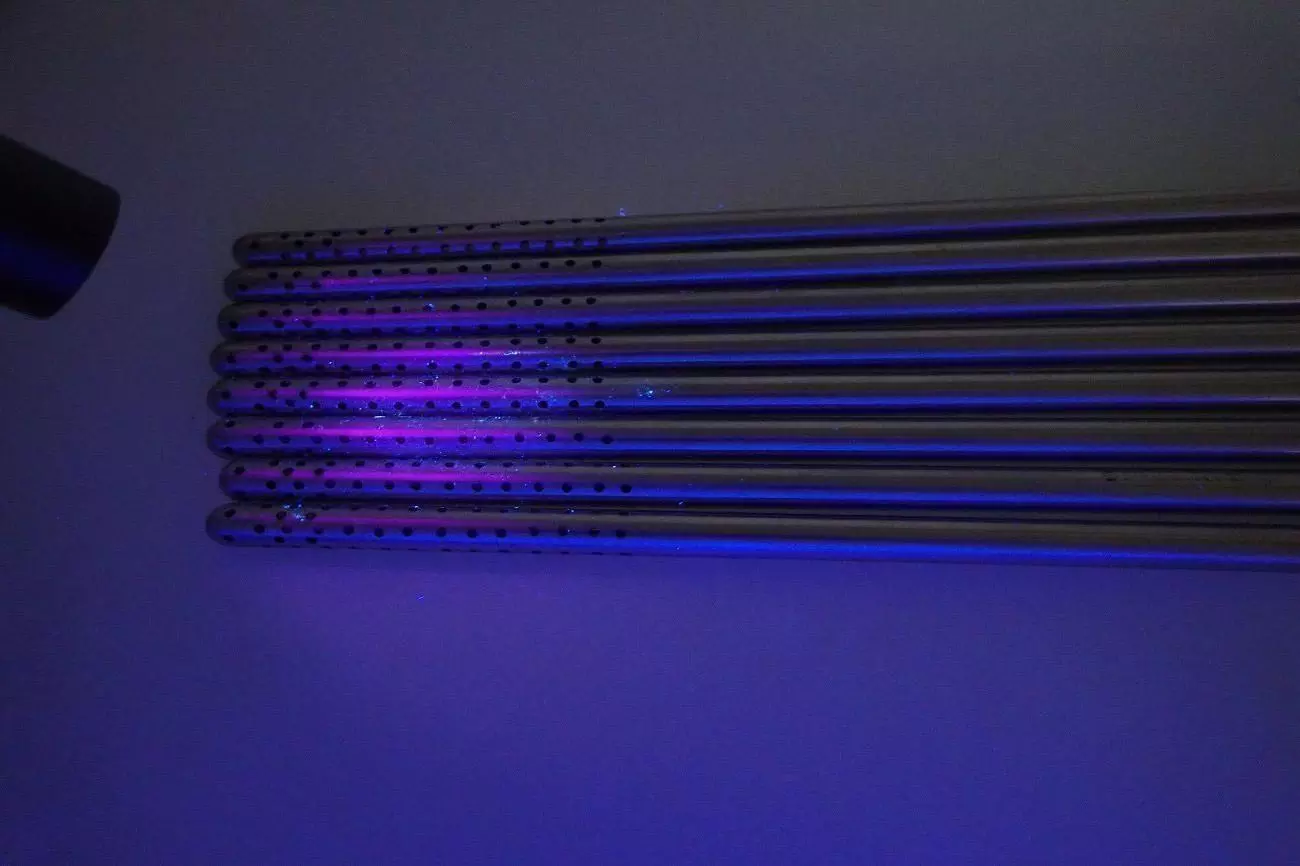

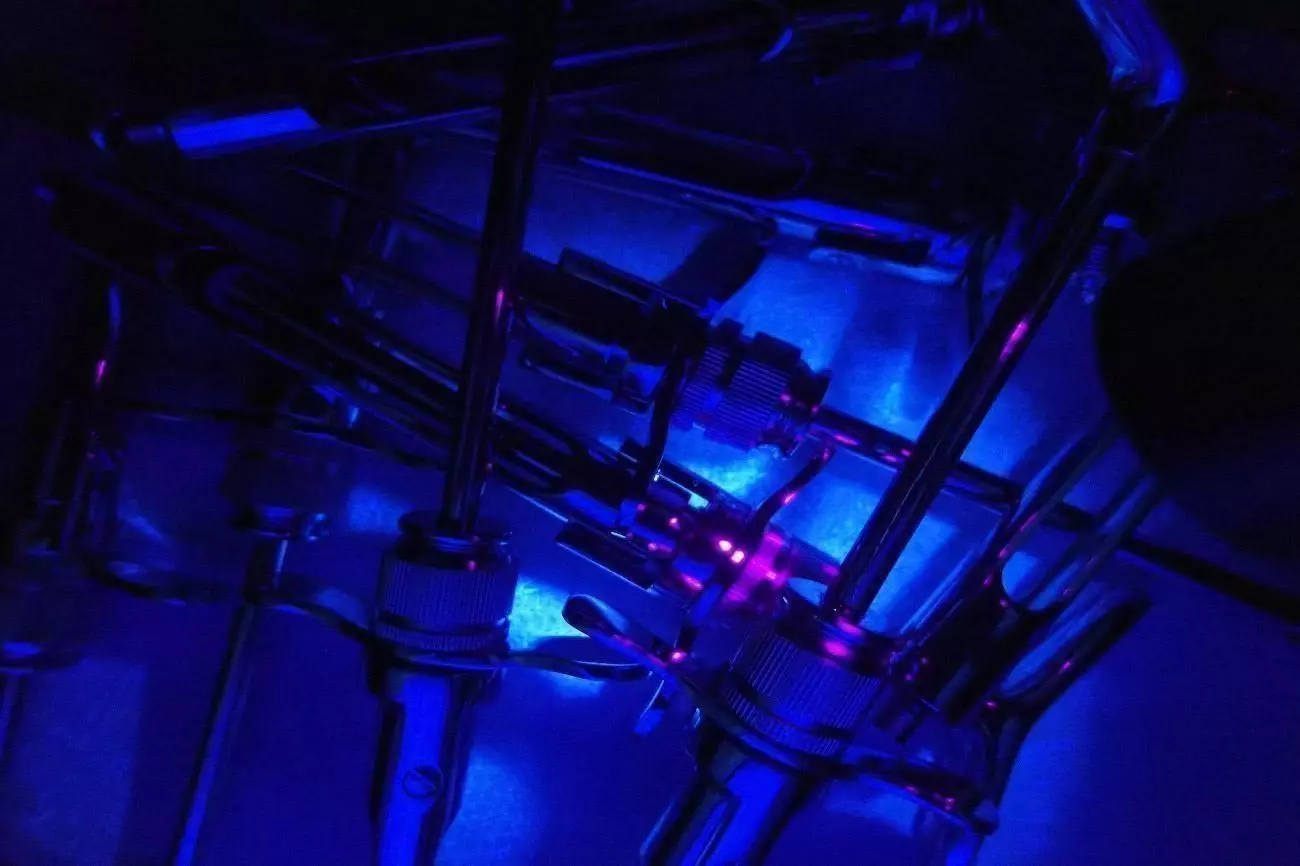

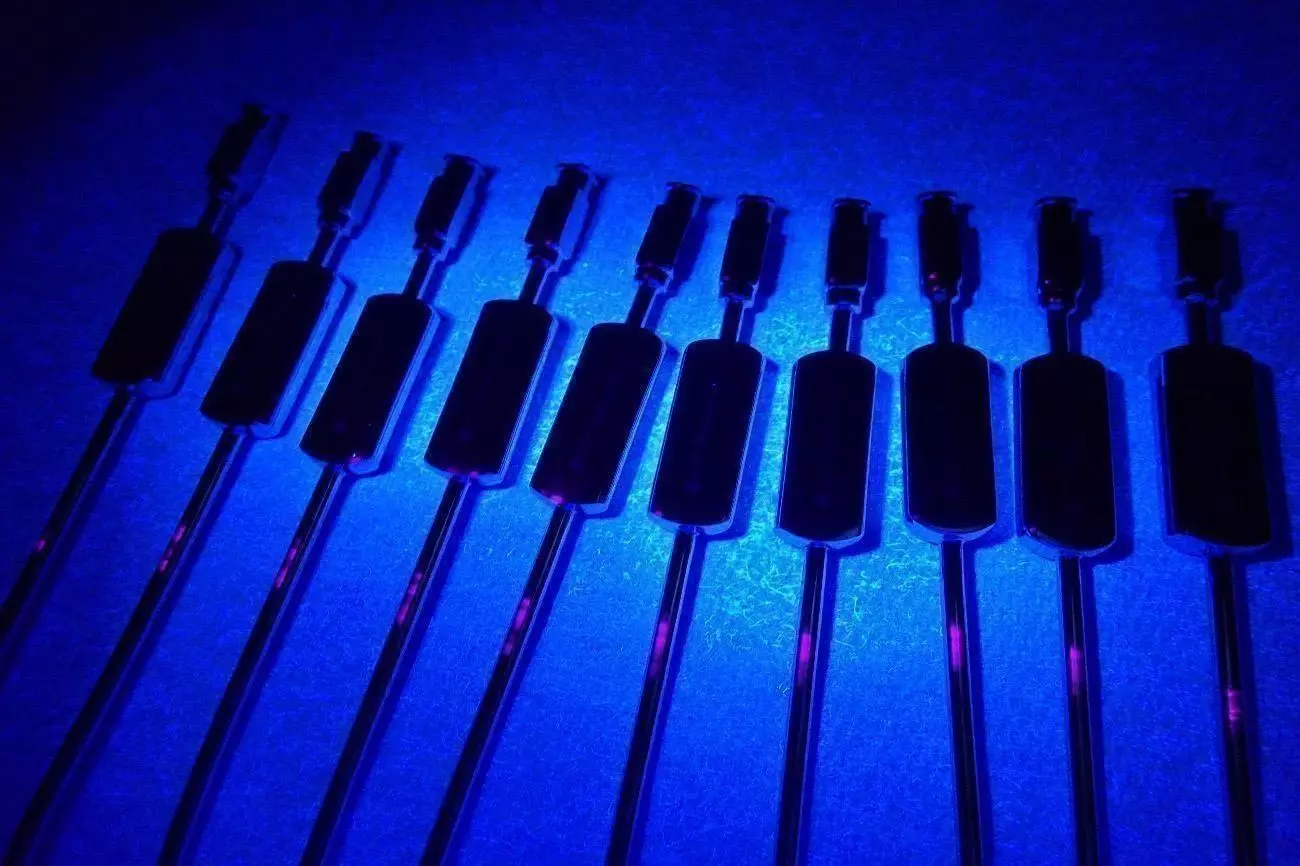

Under UV light, the parts show clear florescent particles before cleaning.

Before cleaning Medical Devices

Click on images below to view larger version