Ultrasonic Cleaning of Filters - Case Studies

Ultrasonic cleaning filters offer several benefits in industrial applications, particularly in effectively removing contamination from various materials.

Process for cleaning Water Filters:

Two cleaning solutions, Galvex 20.02 and H14, were evaluated for their efficacy in cleaning alloy water filters. Galvex 20.02, known for its versatility and effectiveness across different materials, was tested at a 5% dilution on one component which underwent a 10-minute ultrasonic cleaning cycle, followed by a 2-minute rinse with tap water to remove residual detergent. This process successfully eliminated approximately 60% of the contamination present on the component.

H14, characterised by its high alkalinity and robust cleaning properties against stubborn contaminants, was tested next. The component was subjected to a 5-minute ultrasonic wash cycle in a 20% dilution of H14 at 70°C. Similar to the Galvex process, a 2-minute tap water rinse followed to complete the cleaning cycle. The results showed that H14 effectively removed the contamination from the component, surpassing the performance of Galvex 20.02 without adversely affecting the materials involved. Another component underwent a 5-minute ultrasonic cleaning cycle using H14, followed by the same 2-minute rinse in tap water. After cleaning, the component was dried for an additional 5-minute cycle. The outcome demonstrated H14's consistent ability to clean filters thoroughly while maintaining material integrity.

H14 proved to be highly effective in cleaning filters without causing any discernible negative effects on the materials tested. However, it's crucial to note that H14's strong alkaline nature makes it incompatible with soft non-ferrous metals. Therefore, careful consideration of material compatibility is essential when selecting cleaning solutions for ultrasonic cleaning applications.

Component: Water Filters

Material: Alloy

Contamination prior to cleaning: River water

| Ultrasonic Cleaner | Cleaning Agent | Temperature(s) | Concentration |

|---|---|---|---|

| 1. Kemet 30 benchtop ultrasonic cleaner | Galvex 20.02 / H14 | 60-70°C | 5-20% |

| 2. Versa Genius+ 120 air bubble agitation Rinse tank | Tap water | 20°C | 100% |

| 3. Versa Genius+ 120 hot air dryer | N/A | 70°C | N/A |

Note: All stages were allowed to reach the required temperature and degas before cleaning.

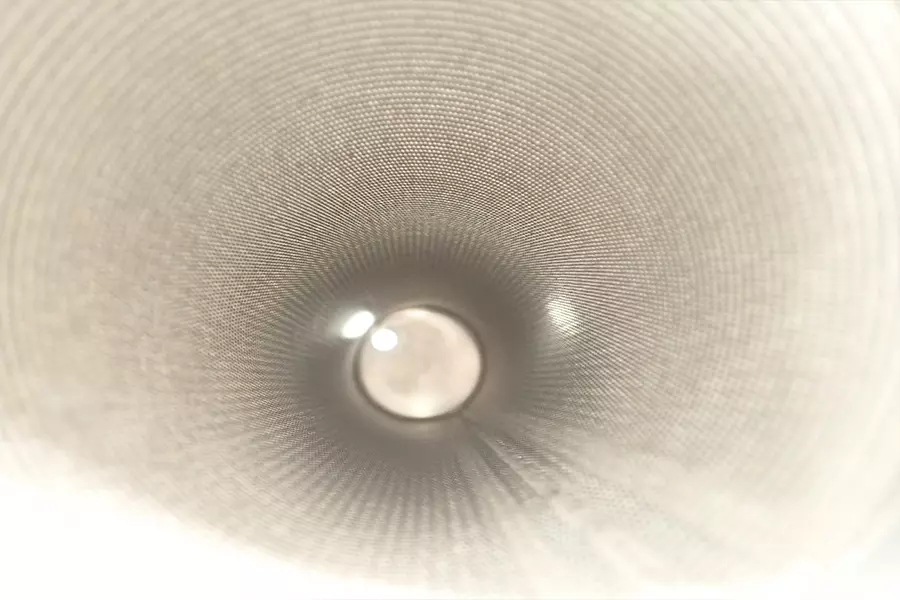

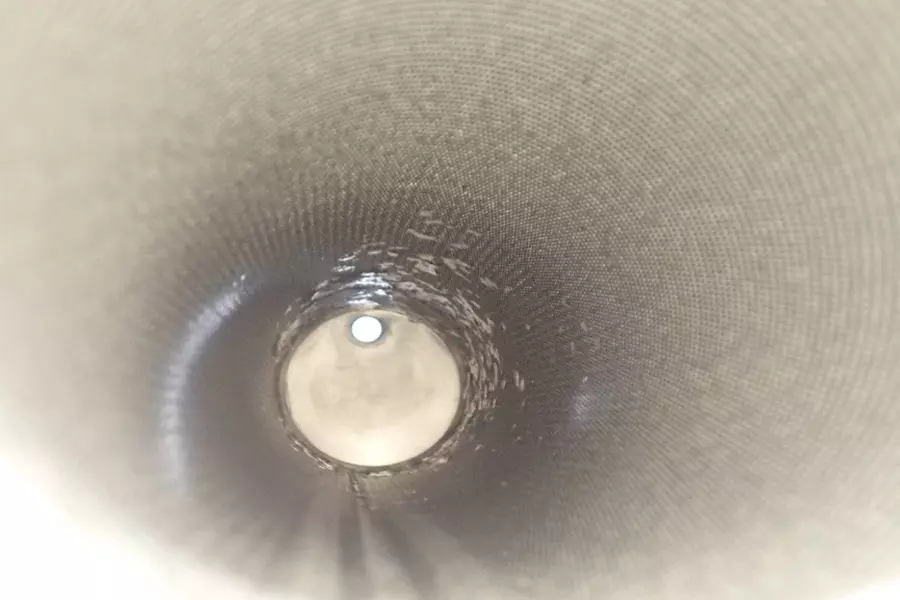

Before cleaning Water Filter

After cleaning Water Filter

Component: Filter

Material: Stainless Steel

Contamination prior to cleaning: Particulates (organic), agarose gel

Process for cleaning Filters:

Stage 1 – H14 Ultrasonic Cleaning: A 10% dilution of H14 was introduced into the tank and allowed to degas, reaching the optimal temperature of 75°C. The filter was then carefully placed inside the wash basket and fully submerged, undergoing a thorough 10-minute cleaning cycle. Stage 2 – Rinsing: Subsequently, the filter underwent a 2-minute rinse cycle using tap water. Utilising the air bubble agitation feature facilitated the flushing of holes, while the auto-purge feature continuously replenished the tank with fresh tap water throughout the treatment, ensuring consistent water quality. Stage 3 – Drying: For the final step, the filter underwent a 10-minute drying process in a recirculating hot air dryer set at 70°C. After inspection, all visible Agarose contamination was successfully eliminated.

| Ultrasonic Cleaner | Cleaning Agent | Temperature(s) | Concentration |

|---|---|---|---|

| 1. M80I Ultrasonic 30Khz | H14 | 75°C | 10% |

| 2. Versa Genius+ 120 air bubble agitation Rinse tank | Tap water | 22°C | 100% |

| 3. Versa Genius+ 120 hot air dryer | N/A | 30-40°C | N/A |

Note: All stages were allowed to reach the required temperature and degas before cleaning.

Before cleaning Filter

After cleaning Filter