How to clean electrical components with an Ultrasonic Cleaner - Case Study

Customers Criteria: Free from all contamination

Component: Electrical component

Material: Copper

Contamination prior to cleaning: Burn marks/staining

Total number off: 4

Number off per run: 1

| Ultrasonic Cleaner | Cleaning Agent | Temperature(s) | Concentration |

|---|---|---|---|

| Kemet 30 | Rodastel 30 | 45°C | 8% |

| Kemet 30 | De-ionised water | 40°C | 100% |

| Versa 120 Dryer | N/A | 60°C | N/A |

Process for cleaning Electrical components:

Wash: Each part was cleaned individually; the part was placed in the basket then submerged in the tank. All parts had a cycle time of 10 minutes. Rinse: After the wash cycle the parts were then rinsed in a stand alone tank using deionised water with no Sonics for a cycle time of 2 minutes. Drying: Finally the tools were dried with a temperature setting of 60°C for a cycle time of 5 minutes. Comments: Some heavy staining has been removed and the parts brightened. Some staining /etching marks still present which cannot be removed without damaging the parts.

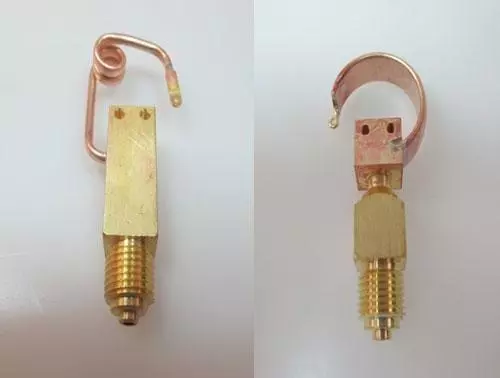

Before cleaning Electrical component

After cleaning Electrical component