Cleaning Automotive Housings with an Ultrasonic Cleaner - Case Study

The automotive industry is continuously evolving and advancing, and with that comes a need for efficient and effective methods for cleaning automotive parts. One such method is ultrasonic cleaning, which has become a popular choice due to its ability to clean complex geometries, intricate parts, and hard-to-reach areas. Ultrasonic cleaning is an effective method for cleaning automotive housings, particularly in removing carbon staining and corrosion. By following a specific set of steps, including allowing tanks to reach the required temperature, degassing, and thorough rinsing and drying, it is possible to achieve a contamination-free result. However, it is important to note that optimal results are achieved by stripping the housings before cleaning, and by increasing the fluid concentration and cycle time. Ultrasonic cleaning is a powerful tool in the automotive industry, and as technology advances, it is likely to become even more efficient and effective.

Customers Criteria: Free from all contamination

Component: Automotive housings

Material: Various

Contamination prior to cleaning: Carbon staining, corrosion

The customer's criteria for the automotive housings was to be free from all contamination. The housings were contaminated with carbon staining and corrosion, which can be a common problem in the automotive industry. These types of contaminants can lead to reduced performance and even failure of the component, making it crucial to effectively remove them.

| Ultrasonic Cleaner | Cleaning Fluid | Temperature(s) | Concentration |

|---|---|---|---|

| Versa 120 Wash | Rodastel 30 | 55°C | 4% |

| Versa 120 Rinse | Tap water | 40°C | 100% |

| Versa 120 Dry | N/A | 70°C | N/A |

Process for cleaning automotive parts:

To achieve the desired outcome, the cleaning process followed a specific set of steps. First, all tanks were allowed to reach the required temperature and degassed before cleaning. This ensures that the ultrasonic cleaning process is performed at optimal conditions, which is essential for achieving the best possible results.

The parts were then placed inside a basket and submerged in the ultrasonic tank for a cycle time of 30 minutes. This cycle time is significant as it provides ample time for the ultrasonic waves to penetrate the contamination, removing it from the surface of the automotive housing. After 30 minutes, the parts were turned to allow the ultrasonics to clean both faces evenly, and left for an additional 30 minutes.

Following the ultrasonic cleaning cycle, the parts were rinsed in a non-ultrasonic rinse tank using an air bubble agitation for three minutes. This step helps to neutralise the surface and remove any remaining debris that may be present after the ultrasonic cleaning cycle.

Finally, the parts were dried in a hot air drying unit for 20 minutes at 65°C before inspection. This step ensures that the parts are completely dry, which is essential in preventing any further contamination.

The process used for cleaning the automotive housings with an ultrasonic cleaner proved to be effective in removing the carbon staining and corrosion. The ultrasonic cleaner was particularly effective in removing the carbon build-up on aluminium, which can be a challenging task to achieve with other cleaning methods.

It is important to note that, for optimal results, the housings should be stripped before cleaning. Stripping the housings allows for complete exposure of the surface, which makes it easier for the ultrasonic waves to penetrate and remove any contaminants.

Moreover, it is possible to further improve the cleaning results by increasing the fluid concentration and the cycle time. Increasing the concentration of the cleaning solution increases the cleaning power of the ultrasonic waves, while increasing the cycle time provides more exposure to the ultrasonic waves, which can lead to more thorough cleaning.

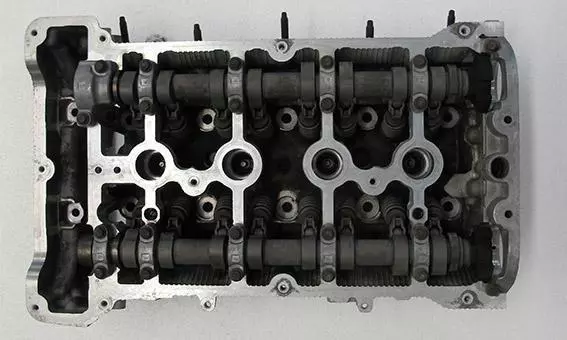

Before cleaning automotive parts

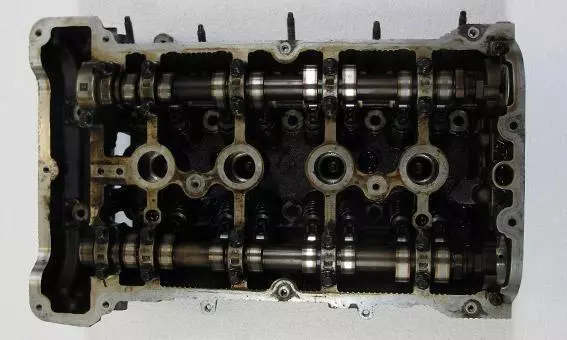

After cleaning automotive parts