Cleaning ALSi10Mg (Graphite / Aluminium Based Alloy Moulds)

Customers Criteria: Free from all contamination

Material: ALSi10Mg

Contamination prior to cleaning: Sintered powder residue

| Machines used for cleaning | Cleaning Agent | Temperature(s) | Concentration |

|---|---|---|---|

| Versa 120 30Khz Ultrasonic with basket dunking | Rodastel 30 | 45°C | 3% |

| Versa 120 Rinse with air bubble agitation | Tap water | 30°C | 100% |

| Versa 120 Dryer | N/A | 80°C | N/A |

The quality of metal parts in the manufacturing industry is crucial. Any contamination on the surface can lead to product failure, thus creating a need for efficient cleaning methods. The cleaning was carried out using an ultrasonic cleaning system and a hydrophilic cleaning agent.

The cleaning was carried out using a Versa 120 30Khz Ultrasonic machine. The machine has a basket dunking feature, which allows the part to move vertically, aiding in the cleaning process. The ultrasonic cavitation feature generates bubbles in the cleaning solution that penetrate the surface of the contaminated part, removing any residue. The cleaning agent used for this process was Rodastel 30. The chemical has hydrophilic properties that allow water on the surface to spread out, removing any fouling debris from the surface. Rodastel 30 was chosen due to its effectiveness in cleaning and conditioning, creating a hydrophilic surface. The cleaning process was carried out at a temperature of 45°C, with a concentration of 3% Rodastel 30. The cleaning solution was placed in the ultrasonic machine's tank and heated to the desired temperature.

Process for cleaning Graphite/Aluminium Moulds

Stage 1 – Rodastel 30: The contaminated ALSi10Mg part was placed standing up inside the basket. The basket dunking feature was used, allowing the basket to have a 32mm vertical travel, aiding in cleaning. The part had a total cleaning time of 10 minutes. During the cleaning cycle, air bubbles escaped out of the three vertical holes, indicating that the ultrasonic cavitation, along with the chemistry, penetrated the holes.

Stage 2 – Tap Water Rinse: After the cleaning process, the part was rinsed in a tap water tank using the air bubble agitation feature for 2 minutes. The air bubble agitation feature acts like a Jacuzzi, sending small air bubbles from the bottom of the tank to the top for the length of the treatment time. This mechanical action helps remove any remaining debris and is a great tool for flushing blind holes and cavities. Rinsing is necessary to neutralise and remove any remaining detergent residue and debris.

Stage 3 – Hot Air Dry: Finally, the part was dried in the hot air dryer set to 80°C for 5 minutes. The hot air dryer removes any residual water, ensuring that the part is completely dry.

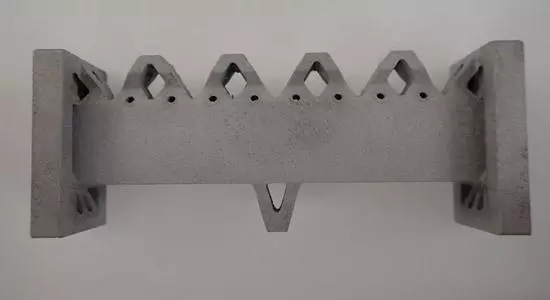

Before cleaning ALSi10Mg

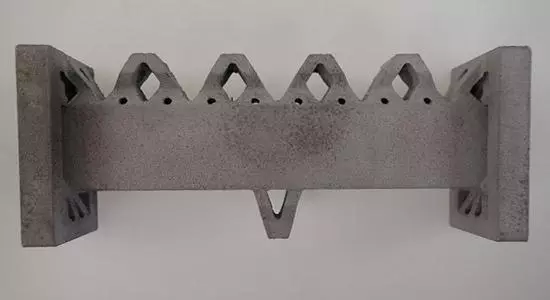

After cleaning ALSi10Mg